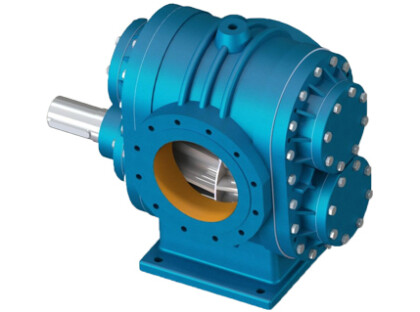

Yildiz YHL External Helical Gear Pump

Resin Pump & Thermal Oil Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 5833lpm |

| Max Head | 150M |

| Max Temperature | 350°C |

| Max Viscosity | 250, 000 cP |

| Solids | 0mm |

| Sizes | 2" to 10" |

This Helical Gear Pump range is designed for pumping low to high viscosity fluids with lubricating properties at high temperatures. There is also the option for these external gear pumps to be supplied with an external heating jacket to maintain the temperature of the pumped medium. Due to the tight clearance between the gears, these helical external gear pumps are not designed for fluids containing abrasive particles. The most common applications include fuel oil transfer, diesel fuel transfer, coolant transfer, OEM, hot oil circulation, food industry, marine, and lubrication.

Features of the Yildiz YHL gear pump:

- Helical external gear pump

- Designed for medium pressure, high temperature applications

- Compact design

- Various material options

- Various sealing options

- Pressure relief valve on cover

- External jacket cover to maintain liquid temperature available

- 230v, three phase 50/60hz motors available

- Motor and gearbox drive available

- Manufactured according to CE regulations

- Explosion proof ATEX rated motors and non-sparking flexible couplings are available

Read our gear pump guide for detailed information on how they operate and the applications they are commonly used for.

FAQs

Gear pumps operate by an unchanging volume of fluid passing between the teeth of two meshing gears and their casing at a constant rate (not between the gears themselves). As the gears rotate and the meshed teeth separate, a partial vacuum is formed that fills with fluid, which they trap and move it around the casing from the suction to the discharge point.