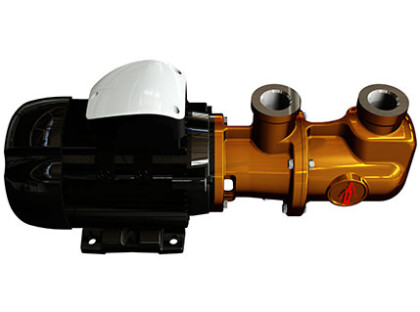

Nova Rotors R Wobble Progressive Cavity Pump

Sludge Pump & Viscous Fluid Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 233lpm |

| Max Head | 40M |

| Max Temperature | 80°C |

| Max Viscosity | 5000 cP |

| Solids | 10mm |

| Sizes Available | 1" to 3 1/2" |

The Nova Rotors R series progressive cavity pumps, also known as wobble pumps, are designed for applications where a compact design or lower flow rate is required, whilst still having relatively high pressure capabilities. The Nova Rotor wobble pump range includes the standard R models and then the RL series, which comes with three fluid discharge points and a patented join for absorbing the axial forces.

The R series of helical rotor pump can handle a wide range of different fluids including those that are slightly abrasive, viscous and contain solids in suspension, as well as shear sensitive mediums thanks to its non-pulsating flow. As well as cast iron, these progressing cavity pumps can come with a stainless steel casing for food grade applications or bronze for marine applications. Popular applications of the wobble pump range include oily sludge transfer, bilge water transfer, sewage transfer, fuel transfer and alcohol transfer, making is a very versatile pumping solution.

For more information on the design of this pump and its typical applications read our progressing cavity pump guide here.

- Low pulsations for handling shear sensitive products

- No vibrations

- Very high priming capability

- Capable of pumping fluids containing solids in suspension

- Capable of handling viscous fluids

- Lightweight and compact design in comparison to traditional progressive cavity pumps

- Available in stainless steel for food grade applications

- Bypass valve or pressure relief valve available

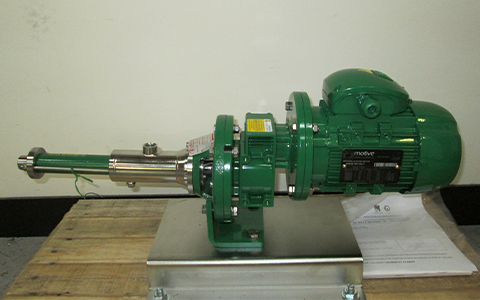

- RL series with patented joint absorbing most of the axial forces ensuring long lifespan

- RL series available with multi porting arrangement

- 230v, three phase 50hz / 60hz motors available

- Marine certification available

FAQs

It consists of a spiralled helical rotor (like a cork screw) that sits tightly inside a rubber stator/sleeve. As the rotor turns inside the stator, it forms a set of fixed-shaped cavities that progress along the length of the stator and force the fluid inside to move along with them as they turn.