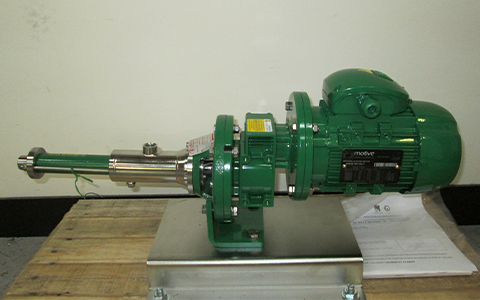

Nova Rotors DM-JM Progressive Cavity Dosing Pump

Dosing Pump & Water Treatment Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 45lpm |

| Max Head | 240M |

| Max Temperature | 150°C |

| Max Viscosity | 1,000,000 cP |

| Solids | 3mm |

| Size | 3/8" |

The Nova Rotors DM-JM series are progressive cavity pumps commonly used as dosing pumps thanks to their constant and precise flow output. These models have superceded the told Nova Rotors MN dosing pumps. The design of this progressing cavity allows for the pumping of dense and viscous fluids containing solids at very small and precise flow rates. The DM series of helical rotor pump is also excellent at handling shear sensitive fluids; this is due to the fact the pump generates low pulsations so there is less agitation caused to the pumped medium. Frequent applications of this Nova Rotor mono pump include oily sludge transfer, bilge water transfer, sewage transfer, bio-waste and alcohol transfer.

This dosing pump is also available as a food grade progressing cavity pump constructed from polished stainless steel 316 and a food grade stator. Typical food transfer pump applications include fruit juice pulp, beer, fruit paste, grapes, grape paste, wine and edible oils.

Read our progressing cavity pump guide for more detail on how this pump operates and its popular uses.

- Low pulsations, suitable for shear sensitive fluids as it will not change fluid state

- No vibrations

- Very high priming capability and flow reversibility

- Precise and accurate flow rate for metering applications

- Capable of pumping fluids containing solids in suspension

- Capable of handling viscous fluids up to 1,000,000cp

- Small, compact and lightweight construction

- Double mechanical seal available

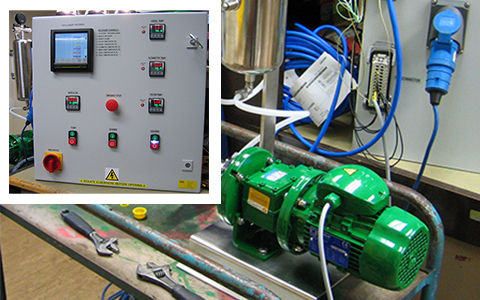

- 230v, three phase 50hz / 60hz motors available

- Available in FDA approved materials for use as a food grade pump

- Marine certification available

FAQs

It consists of a spiralled helical rotor (like a cork screw) that sits tightly inside a rubber stator/sleeve. As the rotor turns inside the stator, it forms a set of fixed-shaped cavities that progress along the length of the stator and force the fluid inside to move along with them as they turn.