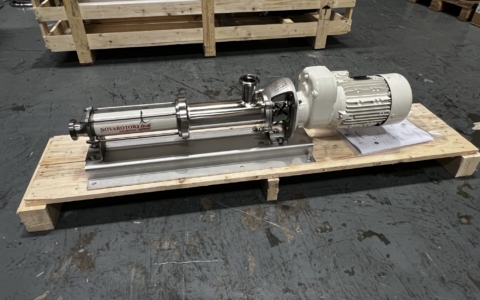

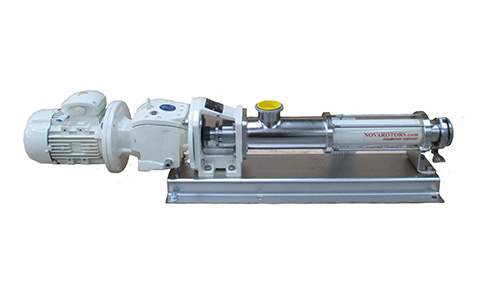

Nova Rotors DX-JX Food Grade Progressive Cavity Pump

Hygienic Pump & Food Grade Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 11333lpm |

| Max Head (Pressure) | 480M |

| Max Temperature | 150°C |

| Max Viscosity | 1,000,000 cP |

| Solids | 30mm |

| Sizes | 3/4" to 24" |

The Nova Rotors DX/JX series of sanitary progressive cavity pumps are the hygienic range of helical rotor pumps within the Diamond series. The series, which consists of models DX, JX, DXO and DXC are state of the art mono pumps for the handling of viscous, shear sensitive and solids in the food processing, pharmaceutical, chemical and cosmetic industries. Designed for the pumping of wine, dairy and beverages, and with typical applications in breweries, distilleries and the tomato and sugar industries, these hygienic progressing cavity pumps have a complete sanitary design and comply with EHEDG and 3A standards, ensuring maximum sanitation and clean in place capabilities.

Specifically designed to allow drainage and avoid dead zones, these Nova Rotor progressive pumps are top rated, with each component manufactured to the highest level finish and cleanliness.

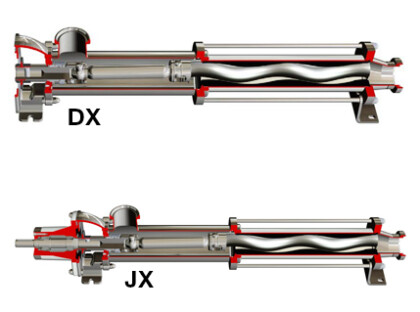

DX Series: Drive is directly coupled to the eccentric screw pump via a flange. A cheap and compact solution, with reduced installation costs and simplified maintenance.

JX Series: Drive is connected to shaft inlet via coupling joint. Best solution for performance and durability. Requires greater installation space.

DXO & DXC: Solutions with the best sanitary characteristics, due to it being free of dead zones and stagnation. Both suitable for abrasive fluids.

DXO Series: Open joint hygienic pump meaning guaranteed lubrication and long duration. Pumping lubricant products improves performance considerably.

DXC Series: Hygienic pump with patented pin joint.

For more information on the working principle and typical applications, read our progressive cavity pump guide.

- Complete sanitary design ensuring maximum sanitisation

- Can be manufactured to fit existing pipework for replacement mono pumps

- Various sealing options including: mechanical, single outer mechanical, single mechanical with quench, back to back double mechanical and double mechanical with tandem

- Hydraulic parts allow excellent self-priming – up to 7m

- Capable of pumping various fluids from low to high viscosities

- Capable of pumping clean fluids and fluids containing solids of varying size and nature

- Low pulsation flow ensures the delicate handling of shear sensitive fluids

- Clean in place connection built into pump body

- Stainless steel heavy duty base plates - AISI 304 & AISI316

- EHEDG & 3A standards, and ATEX certified

- Reduced maintenance costs thanks to patented pin joint

*Series K8 – Max pressure: 48 bar

Key Benefits:

FAQs

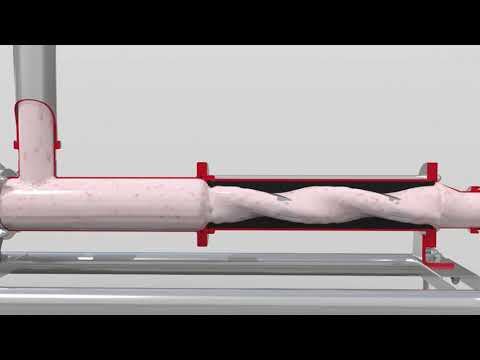

It consists of a spiralled helical rotor (like a cork screw) that sits tightly inside a rubber stator/sleeve. As the rotor turns inside the stator, it forms a set of fixed-shaped cavities that progress along the length of the stator and force the fluid inside to move along with them as they turn.