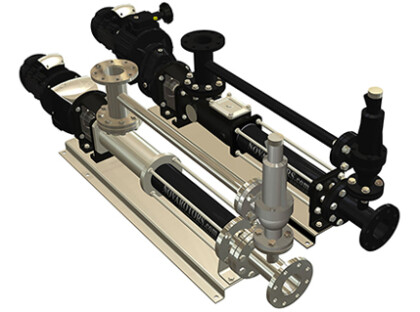

Nova Rotors DN-JN Progressive Cavity Pump

Fuel Transfer Pump & Viscous Fluid Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 11333lpm |

| Max Head | 480M |

| Max Temperature | 150°C |

| Max Viscosity | 1,000,000 cP |

| Solids | 30mm |

| Sizes | 3/4" to 24" |

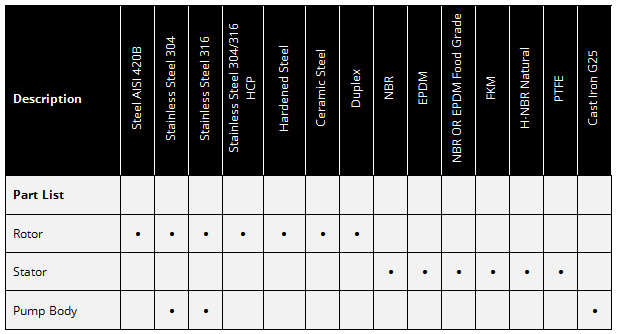

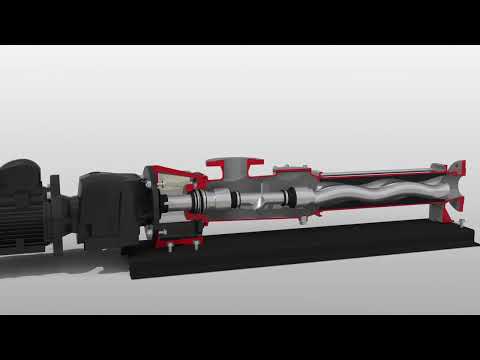

The Nova Rotors DN-JN Series Progressive Cavity Pump is the standard model in the Diamond series. Thanks to being API676 approved it is suitable for the pumping of a hydrocarbons as well as a vast range of viscous fluids and those containing solids. The DN helical rotor pump model's drive is directly coupled to the pump via a flange as an economical and compact solution, with ease of maintenance. The JN series of mono pump on the other hand has a drive connected to the shaft inlet via a coupling joint and has modular bearing housing, which has greater durability as the bearings take the stress generated by the pump. However this model requires additional space within the installation.

Both of these progressing cavity pump models benefit from a smooth pumping action to ensure that the state of the fluid is not altered during pumping, this is especially important when pumping shear sensitive fluids. The main applications for this mono pump unit include the transfer of fuels, hydrocarbons, waste sludge, sewage and water.

Read our progressing cavity pump guide for more information on the operating principle and typical applications.

- API 676 & ATEX approved progressive cavity pump

- DN series - drive is coupled directly to the pump via a flange

- JN series - drive is connected to the shaft inlet via a coupling joint

- Pump can be mounted on baseplate or trolley and fitted with bypass valve

- One stage stator with long pitch geometry to improve performance

- The stator is sealed at both ends, no o-ring is required

- Newly designed rubber sleeve to allow for any sharp solids in the liquid

- Seal options include single mechanical seal, packing seal, double mechanical seal and cartridge

- Integrated bearing lubrication system

- Good self priming capabilities

- Reversible flow up to 3 bar as standard: Up to 12 bar with hydraulic balance

- Capable of handling liquids with solids in suspension

- Can transfer viscous fluids up to 1,000,000cp

- Low pulsations for shear sensitive fluids

- 230V, 3 Phase 50hz / 60hz motors available

- Marine certification available

Key Benefits:

FAQs

It consists of a spiralled helical rotor (like a cork screw) that sits tightly inside a rubber stator/sleeve. As the rotor turns inside the stator, it forms a set of fixed-shaped cavities that progress along the length of the stator and force the fluid inside to move along with them as they turn.