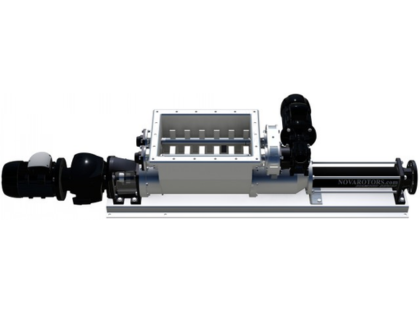

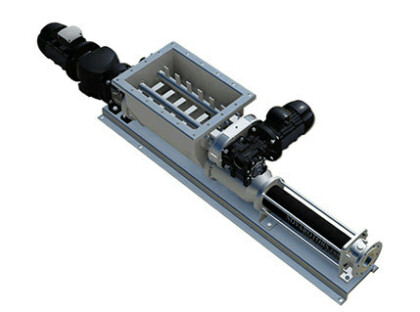

Nova Rotors DHB-JHB Progressive Cavity Pump With Hopper & Motorised Bridge Breaker

Sludge pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 11333lpm |

| Max Head | 480M |

| Max Temperature | 150°C |

| Max Viscosity | 1,000,000 cP |

| Solids | 30mm |

| Sizes | 3/4" to 24" |

The Nova Rotors DHB-JHB Series is a progressive cavity pump from the Diamond series which comes as standard with hopper and enlarged auger screw for feeding the product into the pump. This allows the pump to handle extremely high viscosity matter with a high concentration of dry solids (up to 40%) that do not flow easily. This model of progressive cavity pump has the addition of a motorised paddle integrated inside the hopper to ease the slow of solids into the pump. This makes it ideal for pumping substances which tend to form a bridge such as doughs or whole fruits and vegetables.

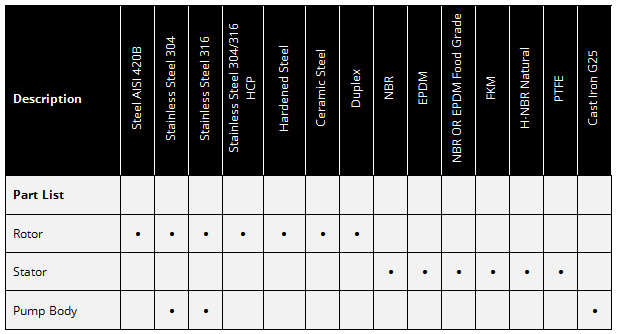

This progressing cavity pump has the highest solid handling in the market, a low maintenance pin joint and is fully reversible. These features combined with the wide range of materials it is available in, makes the mono pump suitable for pumping a vast range of products including bio-waste, dehydrated sludge, minced meat, fruits and vegetables.

For more information on when you would use this type of pump and its working principle, read out progressing cavity pump guide here.

- Hopper and motorised paddles for matter containing high concentration of dry solids around 40% that may form a bridge

- One stage stator with long pitch geometry to improve performance

- The stator is sealed at both ends, no o-ring is required

- Newly designed rubber sleeve to compensate for any sharp solids in the fluid

- Various sealing options including; single mechanical seal, packing seal, double mechanical seal and cartridge

- Integrated bearing lubrication system

- Very high priming capability

- Reversible flow up to 3 bar as standard: Up to 12 bar with hydraulic balance.

- Capable of pumping fluids containing solids in suspension.

- Capable of handling viscous fluids up to 1,000,000cp

- Low pulsations for shear sensitive fluids

- 230V, 3 Phase 50hz / 60hz motors available.

- API, ATEX, Food Grade EHEDG, 3A and Marine certification available

Key Benefits:

FAQs

It consists of a spiralled helical rotor (like a cork screw) that sits tightly inside a rubber stator/sleeve. As the rotor turns inside the stator, it forms a set of fixed-shaped cavities that progress along the length of the stator and force the fluid inside to move along with them as they turn.