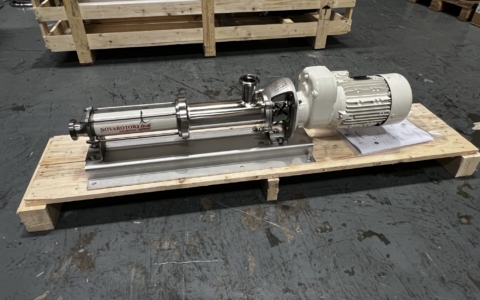

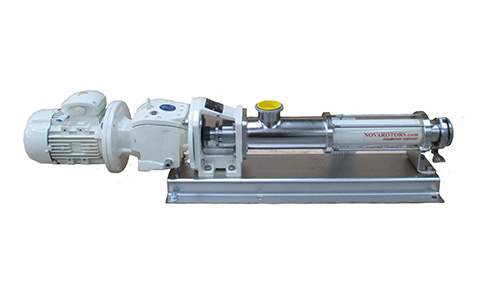

Nova Rotors Diamond Food Grade Progressive Cavity Pumps

Food Grade Pump & Hygienic Pump

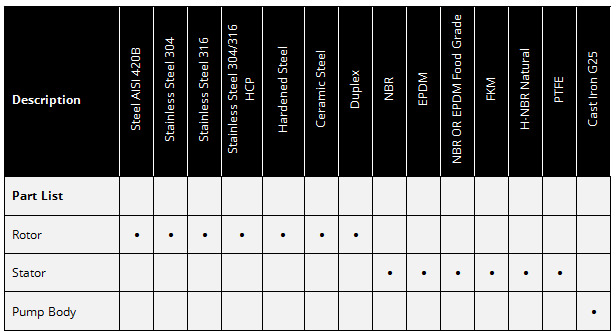

| Key Specifications | |

|---|---|

| Max Flow Rate | 11333lpm |

| Max Head | 480M |

| Max Temperature | 150°C |

| Max Viscosity | 1,000,000 cP |

| Solids | 30mm |

| Sizes | 3/4" to 24" |

Available within the newest range of progressive cavity pumps from Nova Rotors, is the Diamond food grade pump. This new design enables Nova Rotors to offer their helical rotor pumps for hygienic applications with performance requirements up to 400m³/hr and pressures up to 48 Bar. Manufactured in food grade stainless steel, this mono pump is suitable for food applications including milk, yoghurt, cheese, butter, chocolate and mashed fruit/vegetable transfer. The sanitary standards also make the Diamond progressing cavity pump suitable for the cosmetic industry including oil, emulsion and liquid soap transfer.

Available here is a guide to how progressive cavity pump works and the applications for which they are often selected.

- Sanitary food grade pump

- Clean in Place (CIP) on request

- Reduced maintenance thanks to patented pin joint that can work for 8000 hours without repair

- One stage stator with long pitch geometry to improve performance

- The stator is sealed at both ends, no o-ring is required

- Newly designed rubber sleeve to allow for any sharp solids in the fluid

- Various sealing options including; single mechanical seal, packing seal, double mechanical seal and cartridge

- Integrated bearing lubrication system

- Very high priming capability

- Reversible flow up to 3 bar as standard: Up to 12 bar with hydraulic balance.

- Capable of pumping fluids containing solids in suspension.

- Capable of handling viscous fluids up to 1,000,000cp

- Low pulsations for shear sensitive fluids

- 230V, three phase 50hz / 60hz motors available.

- Available in 8 different versions including flanged, hopper, oenological hopper, portable for wine transfer and vertical

- ATEX, API, food grade EHEDG certify. 2013 certifications available

Key Benefits:

FAQs

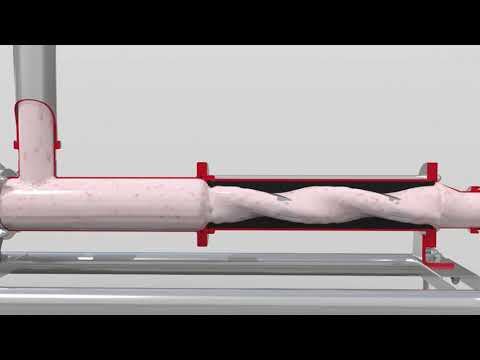

It consists of a spiralled helical rotor (like a cork screw) that sits tightly inside a rubber stator/sleeve. As the rotor turns inside the stator, it forms a set of fixed-shaped cavities that progress along the length of the stator and force the fluid inside to move along with them as they turn.