Liverani RID Flexible Impeller Pump

Abrasive Solids & Food Grade Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 1083lpm |

| Max Head | 32M |

| Max Temperature | 100°C |

| Max Viscosity | 50,000 cP |

| Solids | 25mm |

| Size | 1” to 4" |

The Liverani RID Series is a range of gear box driven flexible impeller pumps. By using a gear box with twin output shafts, double headed options are available to generate either larger flow rates or higher heads. The RID MAXI DOUBLE 2Q effectively doubles the flow of the RID MAXI 80, whereas the RID MAXI DOUBLE 2H effectively doubles the head.

Flexible impeller pumps are very versatile in applications that are suitable for thanks to several design benefits. Firstly, thanks to their supple vanes they are able to handle not only clean, light fluids, but also viscous, solid laden slurries. Secondly, the multiple materials the impellers are made out of mean they are compatible with many fluids e.g. NBR for fats and fuels, EPDM for chemicals and hot fluids and natural rubber for water based liquids. Flexible vane pumps with EPDM and NBR impellers are able to be supplied with FDA Certification, making them a popular electric food grade pump solution. Their low shear operation also makes the ideal for handling delicate fluids that can be altered by other pump designs.

Flexible impeller pumps are renowned for their dry self-priming capability, making them ideal for applications where good suction lift capacity is needed such as the emptying of tanks, sumps and other containers. The RID flexible vane pumps are widely used in transferring, filling & emptying applications for medium to high viscosity fluids or for operating at low rotational speeds for shear sensitive fluids. As the pumps are close coupled, the various inlet and outlet configurations can be better taken advantage of (a possible draw back to the GR series of flexible impeller pumps).

More information on how a flexible vane pump works and the applications it is often selected for is available here.

Features of the RID Series Flexible Vane Pump:

- Gearbox driven flexible vane pump

- Pulsation free pumping action for the transfer of shear sensitive liquids.

- Solids passage capability - 10mm (MINOR) 15mm (MAJOR) 25mm (MAXI)

- Self-priming up to 6m without the requirement of a non return valve.

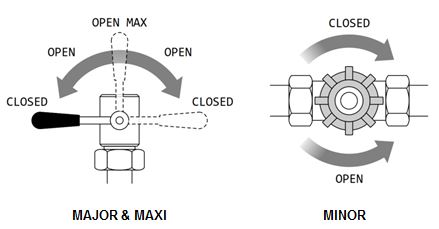

- Pumps can run in both directions via a reversing switch mounted on the panel.

- Select flexible impeller pump models are also available with 2 speed operation, controllable via a rocker switch.

- Pump head can be rotated and installed in a range of positions.

- Wide range of connection types available including DIN, BSP Male & Female, Triclover, SMS, RJT, Friederich, Garolla, and Macron

- Stainless Steel AISI 304 Pipe Fittings for easy integration of the pump into existing applications are available.

- NOTE: units are supplied with Garolla connections as standard with hose fittings, clamps and seals included.

- Pump heads are SS304 as standard. SS 316 available on request,

- Unit can be supplied with or without a control panel

- Dry-run protection available.

- Optional automatic drum filling kits complete with stainless steel nozzle, non return valve & pressure switch.

- Accessories include inverter drive for variable speed operation, dry run protection, pressure switch for automatic pumping, level sensors, remote control & radio operation.

Spring loaded by-pass for the MINOR for manual adjustment of the pump capacity as well as operation with a nozzle.

FAQs

Flexible impeller pumps are part of the positive displacement pump family. They consist of a rotating rubber impeller with supple vanes attached. As the casing is smaller than the vanes, they must bend and then straighten as the impeller turns to conform to shape of the pump internal walls. The vacuum created push the fluid round from the inlet to the outlet.