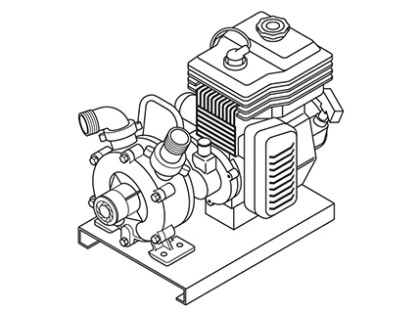

Liverani Falco Side Channel Pump

Chemical Transfer Pump & Seawater Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 140lpm |

| Max Head | 22M |

| Max Temperature | 130°C |

| Max Viscosity | 100 cP |

| Solids | 0mm |

| Size | 1 1/4” to 1 1/2” |

The Liverani Falco Series are engine driven side channel pumps; a low cost, self priming option. These liquid ring pumps are used for a variety of transfer and offloading applications of clean and low viscosity fluids, typically in the marine industry.

The pump head is from the Nautic range therefore features the double bearing support (front and back) of the pump shaft, double lip seal (front and back) and all bronze construction. The Falco series area lightweight, robust and versatile bronze self priming side channel pump.

Features of the Falco Series Liquid Ring Pump:

- Liquid ring pump with 2 stroke manual start petrol engine

- Carrying handle and integral baseplate

- Self priming up to 6m without the need of a non return valve.

- Reversible operation

- Low risk of cavitation due to low NPSHr

- Short period of dry running

- Transfer of fluids with gases and vapour in suspension without a pulsing effect

- Supplied with BSP M Fittings as standard and free issued hose tail / pipe fittings

- Operating Speeds up to 1400 rpm

FAQs

Side channel pumps, or liquid ring pumps as they are otherwise known, are somewhat of a hybrid between a positive displacement pump and a centrifugal pump. Upon start up, a side channel pump begins to operate like a positive displacement pump as it self primes, but soon begins to act like a centrifugal pump once the side channels become filled with fluid.