Liverani All in One Flexible Impeller Pump

Distillery Pump & Food Grade Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 690lpm |

| Max Head | 16M |

| Max Temperature | 100°C |

| Max Viscosity | 50,000 cP |

| Size | 25mm |

| Size | 3/4" to 2 1/2" |

The Liverani All in One is an innovative flexible impeller pump, designed primarily for the wine making and distillery market as a system to monitor and schedule all transfer operations. It is supplied mounted onto a stainless-steel trolley meaning it can be easily transported and used throughout the winery, and is supplied with inverter drive to allow the user to vary the motor speed to change the flow capacity.

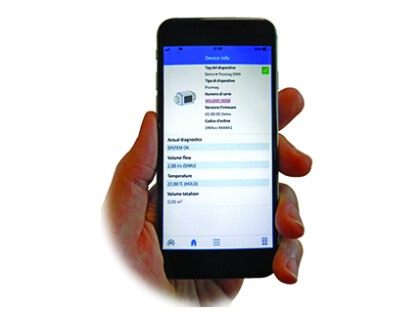

Complete with 7” multi-function touch screen control panel, this flexible vane pump allows the operator to programme the amount to be transferred as well as record and review actual transfer applications that have taken place. The start/stop, speed variation and rotation of this complete flexible impeller pump solution can also be remotely operated from a radio control.

The following operations can be undertaken:

- Free transfer – where the user would manually stop the pump after they’ve dispensed what they want to

- Preset volume transfer – where the user sets how much they want to transfer, and the pump will automatically stop once it reaches that amount

- Barrel filling - repeated filling of a preset volume to fill multiple barrels

- Pump over - can be set up pause cycles and to empty pipes after transfer is over

For traceability, it is possible to record and save each transfer operation along with the operation name, type of wine or reference batch. This data can be exported from the control panel onto a USB for analysis on a computer. There is also the ability to connect to additional devices such as a press, filter, or bottling.

The Liverani All in One includes a high precision magnetic food grade flow meter for monitoring the amount of fluid that has been dispensed in that operation, as well as give an indication of flow rate. This flexible impeller pump also benefits from dry run detection which will stop the pump to prevent damage.

The flexible impeller design is ideal as a wine transfer pump as its supple vanes allows the handling of solids which may be present such as grape skin and seeds. The EPDM and NBR impellers are able to be supplied with FDA Certification, making them a popular food grade pump solution.

Features of the Liverani All in One Wine Transfer Pump

- Gearbox driven flexible vane pump with inverter for variable speed control

- Trolley mounted for portability

- Pulsation free pumping action for the transfer of shear sensitive liquids

- IP55 rated touch screen control panel for programming transfer and reviewing past transfer operation data

- Remote operation can be carried out using the radio control

- Data can be exported from the control panel onto a USB for analysis on a computer

- High precision food grade flow meter

- 24V NC connection for auxiliary devices e.g. press, bottled, filter

- Diagnostic feature to alert of dry run stop, inverter error or auxiliary device

- Solids passage capability - 15mm (MAJOR) 25mm (MAXI)

- Self priming up to 6m without the requirement of a non return valve.

- Pumps can run in both directions via a reversing switch mounted on the panel.

- Pump head can be rotated and installed in a range of positions.

- Wide range of connection types available including DIN, BSP Male & Female, Triclover, SMS, RJT, Friederich, Garolla, and Macron

- Stainless Steel AISI 304 Pipe Fittings for easy integration of the pump into existing applications are available

- Pump heads are SS304 as standard. SS 316 available on request

- Dry run protection on pump body to prevent damage

FAQs

Flexible impeller pumps are part of the positive displacement pump family. They consist of a rotating rubber impeller with supple vanes attached. As the casing is smaller than the vanes, they must bend and then straighten as the impeller turns to conform to shape of the pump internal walls. The vacuum created push the fluid round from the inlet to the outlet.