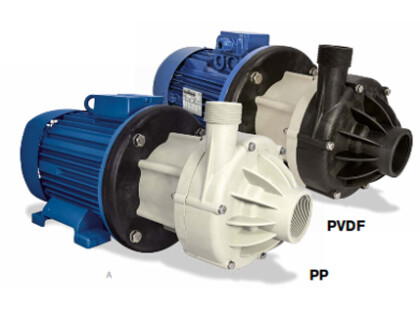

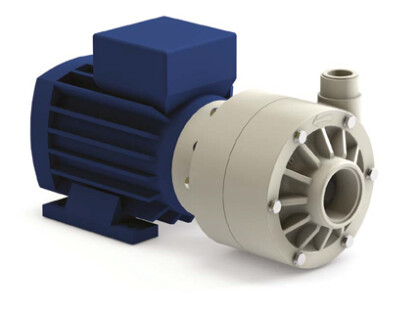

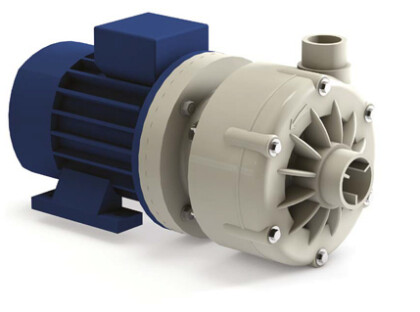

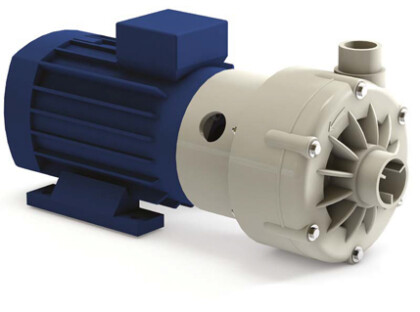

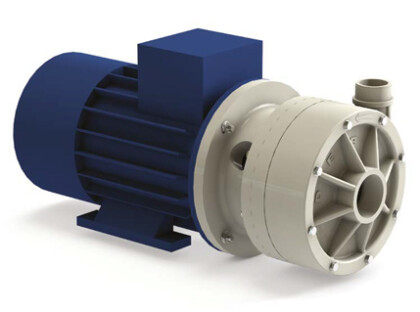

Debem MB Plastic Chemical Centrifugal Pump

Chemical Pump & Corrosive Fluid Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 1250lpm |

| Max Head | 38M |

| Max Temperature | 95°C |

| Max Viscosity | 500cP |

| Solids | 9mm |

| Size | 1" to 2" |

The Debem MB Series of resin encased centrifugal pumps are chemically resistant pumps specifically designed for acids and alkalis or very dirty liquids. The MB series pump has an open impeller design enabling it to handle liquids with a viscosity up to 500cps, and small suspended solids.

Two versions of the MB plastic chemical centrifugal pump are available; with either a lip seal or bellows (mechanical) seal of which selection is based on the liquid being pumped. This chemical pump casing is of single piece construction and weldless meaning any acid transferred will not attack the welds, which is a common weak area in welded pumps. This horizontal centrifugal pump requires a flooded suction in order to operate.

Features of the Debem MB Single Stage Centrifugal Pump:

- Horizontal centrifugal pump

- Available with lip seal or mechanical seal

- Lift capability of 0M - Flooded

- IEC & NEMA motors available in single and 3 phase 50hz/60hz

- Zero welds and single piece construction ensures longevity

- Extremely easy maintenance

- Available in PP or PVDF

FAQs

The drive magnet is attached to the shaft operated by the motor. As the motor turns on, it spins the drive magnet which in turn spins the magnet attached to the impeller. The rotation of the impeller produces the power that drives the liquid through the pump.