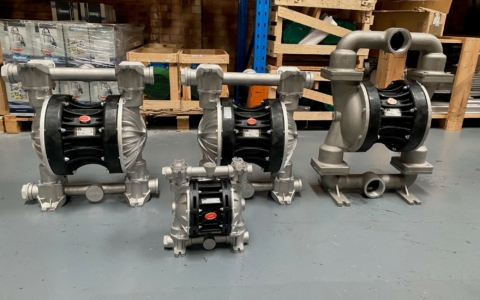

Debem Boxer 150 AODD Pump

High Viscosity Pump & Chemical Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 220lpm |

| Max Head | 80M |

| Max Temperature | 95ºC |

| Max Viscosity | 40000 cP |

| Solids | 5mm |

| Size | 1 1/4" |

The Debem Boxer 150 Air Operated Diaphragm Pump is an Italian manufactured AODD pump designed to very high standards. The Boxer range are very versatile air operated double diaphragm pumps for use within many industrial applications involving chemicals, process fluids, waste water and is commonly used as a high viscosity pump and for liquids containing solids.

The Boxer AODD pump comes with wetted parts available in a range of materials, making it compatible with almost any fluid on the market. Thanks to its ATEX approval to Zone 2 (Zone 1 on request), it is also suitable for use within potentially flammable environments.

This Debem range of air operated diaphragm pumps are what we like to describe as “Fit and forget” solutions. Thanks to their low maintenance, long service life and little manual intervention required, the air operated diaphragm pumps can just be left to do their job.

Features of the Debem Boxer AODD Pump:

- Can be run dry and can pump long distances and dry run without damage, making them unaffected by process stops and pauses in the production line.

- Self-priming capabilities of up to 6m for difficult suction conditions

- Can handle viscosities up to 40000 cp (depending upon installation)

- Patented stall protection - If there is a pressure imbalance the pump will continue running without stalling, reducing downtime and time consuming manual intervention.

- Easily adjustable flow - By amending the air inlet pressure, you can efficiently meet the exact flow requirements of an installation/process.

- Wide range of uses - Can handle viscous fluids with low moisture content, solids up to 5mm and aggressive chemicals due to the various diaphragm materials.

- Low cost to maintain - Long life diaphragms designed for more than 50 million cycles and a lot fewer internal wearing parts to maintain compared to equivalent AODD pump models.

- Fine tuning of motor speed at a constant pressure.

- Actuated via a non-lubricated air system

- 3 suction & delivery port positions

- Can be either submerged into the fluid or surface mounted

- ATEX approved to Zones 1 & 2, II 2/2 GD c IIB T135ºC & II 3/3 GD c IIB T135ºC

Read our AODD pump guide for more information on their working principle and applications they are typically suited to.

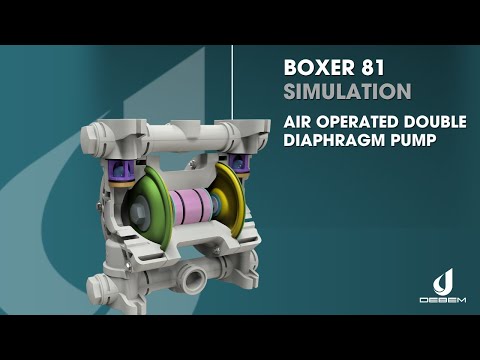

FAQs

The pump is made up of two chambers. As the air forces the diaphragm to move in to the one chamber it forces the fluid inside into the outlet, whilst the other chamber fills up with fluid drawn from the inlet. As the diaphragm moves back into the opposite chamber, the fluid now in that chamber is forced out and the other chamber begins to fill up.