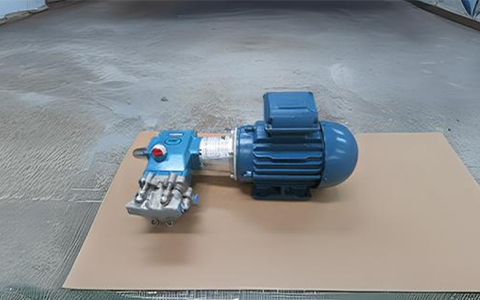

Cat High Pressure Triplex Plunger Pumps

High Pressure Water & Reverse Osmosis Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 912lpm |

| Max Head | 6900M |

| Max Temperature | 115°C |

| Max Viscosity | 500cP |

| Solids | 0mm |

| Size | 1/4” - 2 1/2” & 1/4” - 1 1/4” |

These CAT pumps are industrial, high pressure plunger pumps, designed for operation in extremely high pressure applications up to 690bar. The Cat plunger pump range is therefore often a reliable solution when other pump types fail.

Plunger pumps benefit from a smooth and low pulsating flow thanks to the synchronised movement of the integrated plungers. They are also more efficient than similar types of pump, offering in some cases greater than a 50% improvement on energy consumption.

By taking in a fixed volume of liquid, the high pressure plunger pump ensures that a constant volumetric flow is always delivered. This is attributed to the inlet stroke on the piston moving the set amount of liquid around and out of the pump.

Popular applications for CAT triplex plunger pumps include water mist cooling, chemical injection, pressure cleaning, reverse osmosis and food processing. To select the CAT pump model that is most appropriate for your installation, you need to take consider several factors including the liquid to be pumped, duty cycle, operating temperatures, drive, location and whether the area is classified as safe of hazardous.

In this range are direct drive electric motor and gas engine models, and solid shaft belt driven triplex plunger pumps, available in brass, nickel aluminium bronze and stainless steel.

Features of the CAT Plunger Pump:

- Performance range from 0.5lpm to 285lpm and pressures from 69bar to 690bar

- Direct drive electric motor and gas engine models, and solid shaft belt driven triplex plunger pumps available

- Dependable output- discharge pressure, specific gravity and liquid viscosity do not impact the flow rate

- Speed relative to flow rate – performance can be easily controlled and predicted as the pump output is directly linear to the operating speed

- Resilient drive ends - produced to the highest quality with close consistent tolerance, the crankshafts, crossheads and connecting rods are optimised to minimise wear.

- None abrasive surfaces - there is no relative movement between contact surfaces within the pump head, and therefore the plunger pump can be used with non-lubricating fluids

- Solid ceramic plungers - to ensure that replaced seals are aligned correctly, smooth solid plungers made from alumina ceramics are located concentrically

- No inner liquid mixing- internal mixing of lubricant and process liquid is eradicated due to the substantial gap between the pump head and the oil bath. Any spillages of the liquid are clear as there is a drainage area which is open beneath the pump.

- Highly efficient - minimal internal slippage and low friction ensure that the energy efficiency levels are between 85% & 95% and consequently running costs are lower.

- Continuous duty – these triplex plunger pumps have a continuous duty cycle