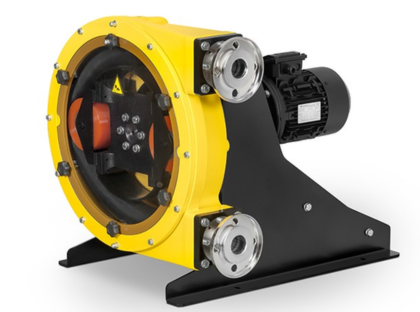

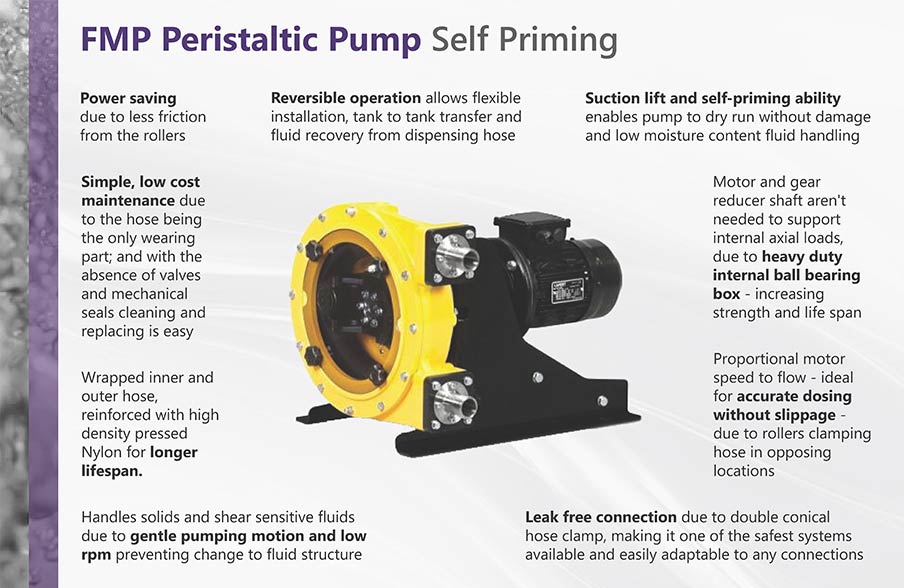

Boyser FMP-40 Peristaltic Pump

Abrasive Solids & Chemical Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 65lpm |

| Max Head | 80M |

| Max Temperature | 80ºC |

| Max Viscosity | 30000 cP |

| Solids | 35mm |

| Size | 1 1/2" |

The Boyser FMP-40 Series Peristaltic Pump is the larger of our two roller operated hose pump, benefitting from wide performance capabilities. Its rugged design makes this self priming peristaltic pump extremely heavy duty and capable of efficient operation in the harshest of environments where other pumps fail due to issues such as dry running damage, clogged valves and seal failures.

One of the largest benefits of the peristaltic hose pump design is that the hose is the only wearing part, which is easy to clean and replace, making it simple and low cost to maintain relative to other pumping technologies. Thanks to its internal hose being available in a variety of materials, its ability to handle solids, fluids with little moisture and shear sensitive mediums these Boyser pumps are extremely versatile. The wide range of applications that it is suitable for include oily sludge, bilge water, oils, shear sensitive liquids, slurries with solids present, dewatering, drainage of tanks, emergency pump leakages, food stuffs, acids, lime milk and muds.

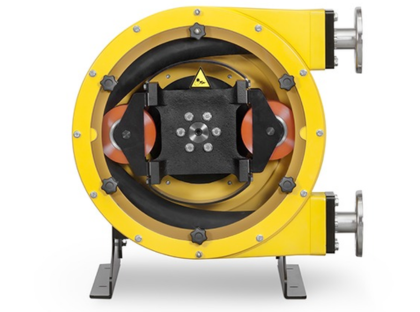

As a roller operated peristaltic hose pump rather shoe operated, the Boyser FMP generates less friction during use. This means that the user is able to benefit from improved energy consumption, a lower starting torque providing a smoother operation and making it easier to adjust speed. It also has simpler hose maintenance as it doesn’t require lubrication.

Features of the FMP peristaltic hose pump:

- Good suction lift and self priming up to 9 metres

- Can dry run without damage and handle fluids with low moisture content

- Inner hose available in a variety of materials for compatibility with almost any fluid.

- Seal-less design makes them less likely to leak – ideal for chemicals and aggressive fluids

- Can handle solids up to pretty much the size of the peristaltic pump inlet/outlet and viscosities up to 30,000cSt

- Gentle pumping motion and low rpm means that they can handle shear sensitive fluids without disrupting the fluid’s natural structure

- Reversible operation allowing tank to tank transfer and the recovering of fluid from the dispensing hose if required at the end of transfer

- Excellent accuracy +/-1% and motor speed is proportional to flow making it ideal for dosing applications

- Patented double conical hose clamp to ensure leak free connection

- Heavy duty internal ball bearing box that means the motor and gear reducer shaft do not have to support of all of the load, adding strength and increasing life span

- Wrapped inner and outer hose, reinforced with high density pressed Nylon for longer life

- Simple and lost cost to maintain thanks to the hose being the only wearing part, which is easy to clean and replace, and the absence of valves and seals that can clog and wear.

- Available with a range of accessories including pulsation dampener, leak detector and inverter

- Variety of drive options which include fixed or variable speed (with speed control)

- 230v, three phase 50hz / 60hz motors available

- ATEX approved, marine certification and food grade certification available

For more information on the workings of peristaltic pumps, please read our guide.

Accessories Available

| Inline Pulsation Dampener | Ensures a continuous, smooth flow for the accurate use of flow meters and pressure switches. By eliminating vibrations and hammering, operation is relatively quiet and working life is increased. |

| Hose Leakage Sensor | Should the only wearing part of the pump (the hose) fail, the sensor can shut off the pump or activate an alarm to allow the situation to be addressed quickly. This makes the pump ideal for remote installations or where hazardous fluids are handled. |

| Vacuum Assisted Priming | Improves the pump's self-priming capability in installations involving particularly viscous fluids or difficult suction conditions. |

| Halar (ECTFE) Coating | Improves the corrosion resistance of the pump in chemical or other hazardous applications. |

| PP/PDV Connections | As standard, connections are Stainless Steel, but for chemical applications they can be supplied in alternative materials. |

| Integrated Control Panel | Can be configured as per the user requirements with features such as on/off, speed control, reversing switch, flow and pressure display, leakage warning. |

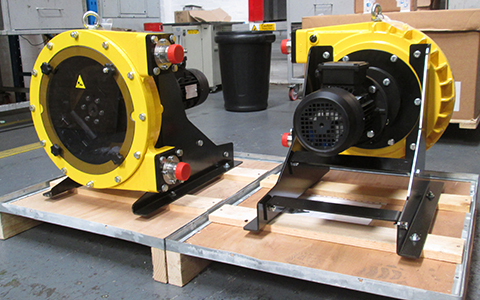

| Trolley or Base Plate | For the flexibility of installation and enhanced mobility where required. |

| Inverter | Pump speed can be slowed down to the required flow, extending the life span of the motor by not making is unnecessarily work to full capacity, and reducing wasted energy costs. |

| Feed Screw & Hopper | For the pumping of highly viscous fluids that don't flow with ease and are prone to breakages. |

FAQs

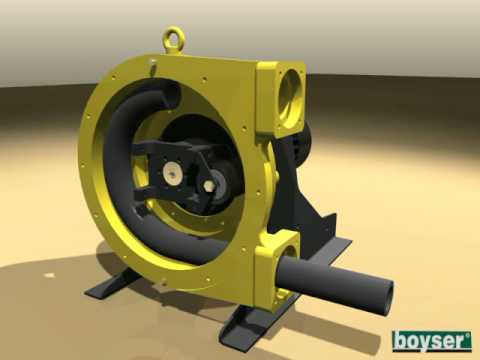

Peristaltic pumps are part of the rotary positive displacement pump family. They are made up of just two components; a rotor that has a number of rollers or a "shoe" attached and a flexible internal hose/tube fitted inside a circular pump casing. As the rotor turns, the attached rollers compress the tube where the fluid is contained, and that continuous motion forces the liquid from the pump's inlet to its outlet.