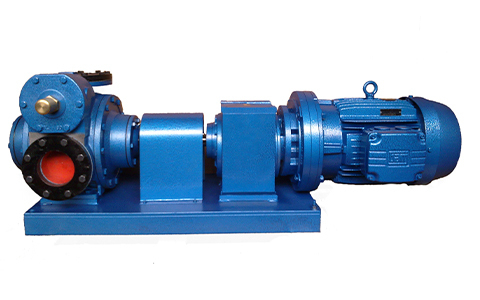

Bombas Trief BAL-2R Rotary Vane Pump

Thermal Oil Pumps & Fuel Transfer Pumps

| Key Specifications | |

|---|---|

| Max Flow Rate | 1833.33lpm |

| Max Head | 100M |

| Max Temperature | 250°C |

| Max Viscosity | 10000 cP |

| Solids | 0mm |

| Size | 1” to 4“ |

The Bombas Trief BAL-2R vane pump is a positive displacement pump designed for pumping most medium and low viscosity fluids free of solids. The BAL 2R rotary pump is robust, quiet and highly efficient; it is particularly excellent at handling fuels and oils up to 250°C. Supplied as standard with two mechanical seals, this vane pump has added protection when pumping high temperature oils and fuels. Frequent uses of this positive displacement sliding vane pump include edible oil refineries, oil refineries, gas depots, fuel transfer, packaging plants, animal feed plants and oil presses.

Features of the Trief BAL-2R vane pump:

- Two mechanical seals as standard for added protection

- Fluid handling up to 250°C

- Built in safety valve

- Robust

- Quiet

- Highly efficient

- Lubricated bearings

- 230V, three phase 50hz / 60hz motors available.

- ATEX approval

For more information on how rotary vane pumps work and the applications they are most commonly used for, read our guide.

FAQs

Rectangular shaped vanes are mounted into slots on a rotor that turns inside the asymmetrical pump casing. As the rotor turns, the asymmetrical casing causes the vanes to move in and out of the slots to touch the casing walls and trap the fluid between this and the rotor. This mechanism draws the fluid round until it is forced out of the discharge port.