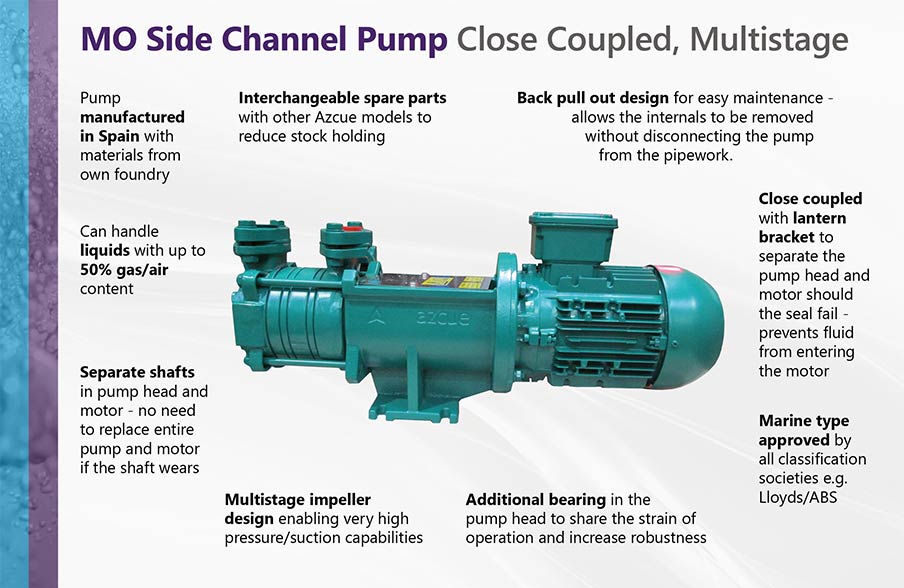

Azcue MO Close Coupled Side Channel Pump

Circulating & Sea Water Cooling Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 9M³H |

| Max Head | 225M |

| Max Temperature | 90°C |

| Max Viscosity | 200 cP |

| Solids | 0mm |

| Size | DN25 to DN40 |

The Azcue MO Close Coupled Side Channel Pump is a larger, more robust alternative to the MA side channel pump. Its multistage design gives it very high pressure/suction capabilities whilst having low flow, which makes it suitable for applications such as pressure boosting and water supply when there is quite a lot of demand on the supply at a time. By nature, these liquid ring pumps can handle up to 50% gas content, making the MO side channel pump ideal for condensate extraction.

The Azcue MO horizontal multistage pump has a back pull out design, allowing the motor to be removed without having to remove the entire pump from the installation, saving time and effort when maintenance is required. Whilst being closed coupled, this liquid ring pump has a lantern bracket, which means that whilst being compact, there is still space between the pump and motor. This means that if the seal wears, no fluid will fall into the motor. It also benefits from having additional bearings to share the strain of operation, therefore enhancing the robustness when in continuous use.

These Azcue pumps have a separate shaft in the pump head and motor meaning that if one shaft goes, there is no need to replace it all; a benefit over other pumps on the market that have one continuous shaft from head to motor.

For more information on how a liquid ring pump works and how this operation makes it suited to specific applications, read our guide.

Features of the Azcue MO Series Liquid Ring Pump:

- Close coupled multistage side channel pump

- Pump manufactured in Spain

- Marine type approved by all classification societies

- Can handle up to 50% entrained air content

- Available in cast iron, 316 stainless steel and bronze for seawater

- Low NPSH

- Compact horizontal design ideal for space saving installations

- Lantern bracket providing some space between pump head and motor

- Back pull out design for simple maintenance

- Separate shafts in the pump and motor

- Additional bearings to share the strain of operation

- Clockwise or anticlockwise rotation

- Mechanical seal or gland packing

- Self priming design

- 230v, three phase 50Hz/60Hz motors available. IP55 as standard.

FAQs

Side channel pumps, or liquid ring pumps as they are otherwise known, are somewhat of a hybrid between a positive displacement pump and a centrifugal pump. Upon start up, a side channel pump begins to operate like a positive displacement pump as it self primes, but soon begins to act like a centrifugal pump once the side channels become filled with fluid.