Azcue CA Close Coupled Self Priming Centrifugal Pump

Ballast Pump & Cooling Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 300M³H |

| Max Head | 105M |

| Max Temperature | 130°C |

| Max Viscosity | 200 cP |

| Solids | 10mm |

| Size | DN32 to DN150 |

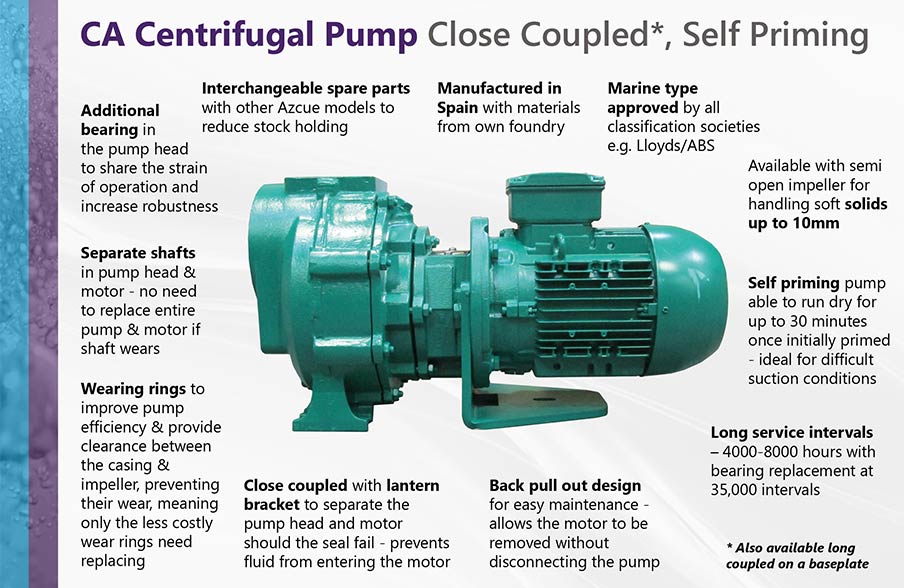

The Azcue CA Close Coupled Centrifugal Self Priming Pump is a competitively priced, compact single stage centrifugal pump with good flow and pressure capabilities. As its inlet is towards the top of the casing, the CA is able to run dry for 30 minutes as they can hold a significant amount of liquid in the casing once initially primed. This means that the CA self priming pump is ideal for the transfer of clean fluids such as water and light fuels over long suction distances, where the tank is situated below the pump and for giving some leeway before the pump needs to be turned off.

With the option of a semi-open impeller, the Azcue CA horizontal centrifugal pump is able to handle up to 10mm of soft solids, making it compatible with water with some degree of contaminants. This series of centrifugal water pump benefit from a back pull out design, meaning that the motor can be removed without disconnecting the pump from the pipework, which is time saving and less complex when maintenance is required.

Whilst being closed coupled, the CA self priming centrifugal pump has a lantern bracket, which means that whilst being space saving in design, there is still some separation the pump and motor so should the seal fail fluid will not enter the motor. It can also be supplied as a bare shaft pump head for fitting to a motor and making it long coupled. This version has additional bearings in the pump head to share the strain of operation, therefore enhancing the robustness of the pump for continuous use.

These Azcue pumps have a separate shaft in the pump head and motor meaning that if one shaft goes, there is no need to replace it all; a benefit over other pumps on the market that have one continuous shaft from head to motor. This model has wear rings, which means there is small clearance between the impeller and pump casing preventing wear to these parts. Wearing rings are designed to be replaced periodically which stops the more costly replacement of the impeller or casing.

Features of the Azcue CA Self Priming Pump:

- Close coupled, single stage centrifugal pump

- Self priming pump which can run dry for 30 minutes after initial priming

- Pump manufactured in Spain

- Marine type approved by all classification societies

- Available with open or closed impeller

- Heavy duty grease lubricated ball bearing design

- Compact horizontal design ideal for space saving installations

- Available in cast iron, 316 stainless steel and bronze for seawater

- Lantern bracket providing some space between pump head and motor

- Back pull out design for simple maintenance

- Separate shafts in the pump and motor

- Long service interval of between 4000-8000 hours - bearing replacement at 35,000 intervals

- Low NPSH

- Casing wear rings to prolong casing and impeller life

- Mechanical seal

- 230v, three phase 50Hz/60Hz motors available. IP55 as standard.

- Also available with diesel engine or clutch/pulley driven

- Assembly without alignment

- ATEX versions available