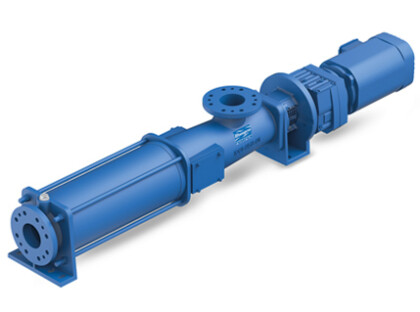

Azcue KB Progressive Cavity Pump

Abrasive Solids & Viscous Fluid Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 147M³H |

| Max Head | 480M |

| Max Temperature | 140°C |

| Max Viscosity | 200,000 cP |

| Solids | 95mm |

| Size | DN20 to DN50 |

The Azcue KB Progressive Cavity Pump is a quality and robustly constructed solution designed the transferring of difficult fluids even over long distances thanks to the high pressures they can achieve. Thanks to its low internal velocity of helical rotor pumps, the KB can transfer viscous liquids containing particles and contaminants efficiently such as sewage and slurries, as well as shear sensitive mediums that have a structure can be impacted when high shear is applied.

The KB is a more compact and cost effective progressive cavity pump compared to the KL model, as rather than having a bearing bracket, the motor is close coupled directly to the pump housing. Available in smaller sizes and at lower flows than the KL, it is ideal for less abrasive conditions and smaller volumes of liquid being transferred, whilst still being able to handle solids up to 95mm.

In order to ensure reliable operation and a long service life, the KB eccentric screw pump has a fully encapsulated cardan shaft and joint with lifetime lubricated needle roller bearings that prevent wear and mean they don’t need to be regularly maintained. It also benefits from joint connections that have continuous diameters, ensuring there is a constant flow within the suction housing and blockages do not occur.

For more information on how progressing cavity pumps operate and the applications for which they are most suited, read our guide.

Features of the Azcue KB Progressing Cavity Pump:

- High pressure progressing cavity pump

- Self priming to handle difficult suction conditions

- Enables the free passage of solids up to 95mm

- Max viscosity of 200,000 mPas

- Compact close coupled pump head to drive

- Lifetime lubricated roller bearings

- Equivalent diameter joint connections to prevent blockages

- Low pulsation, continuous flow

- Suction housing with large inspection and clean openings

- Easy to replace cartridge format seal package

- Available in cast iron or stainless steel

- Electric or hydraulic motor driven

FAQs

It consists of a spiralled helical rotor (like a cork screw) that sits tightly inside a rubber stator/sleeve. As the rotor turns inside the stator, it forms a set of fixed-shaped cavities that progress along the length of the stator and force the fluid inside to move along with them as they turn.