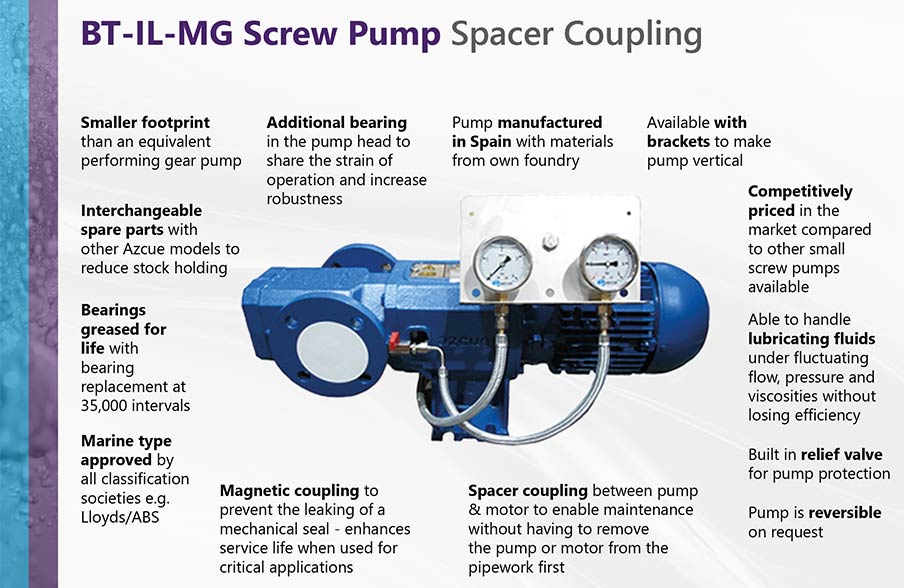

Azcue BT-IL-MG Spacer Coupled Triple Screw Pump

Lubricant Transfer Pump & Fuel Transfer Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 35M³H |

| Max Head | 160M |

| Max Temperature | 160°C |

| Max Viscosity | 1500 cP |

| Solids | 0mm |

| Size | DN50 to DN100 |

The Azcue BT-IL-MG Spacer Coupled Triple Screw Pump is the BT-IL supplied with a magnetic coupling, which eliminates the issue of a mechanical seal leaking and therefore enhances service life for more critical applications. The Azcue BT-IL is larger, higher flow screw pump, for applications where larger volumes of fuel oils and lubricants need to be transferred.

As a positive displacement pump, screw pumps are able to handle lubricating fluids under fluctuating flow rates, pressures and viscosities without losing efficiency making the Azcue BT-IL magnetic drive pump suitable for a range of performance requirements. The nature of the screw pump design means it can be used where suction capabilities are difficult such as pumping over long distances or where the pump is located above the fluid

These self priming screw pumps have a spacer coupling for maintenance of the pump without having to remove the motor first and an additional ball bearing between the pump and motor to share the strain of operation, making it ideal for more heavy duty, continuous use. This magnetic drive triple screw pump is horizontal in design with inline suction and discharge, supplied flanged as standard.

Features of the Azcue BT Series Screw Pump:

- Self priming screw pump

- Pump manufactured in Spain

- Magnetically coupled pump to prevent seal leaks

- Marine type approved by all classification societies

- Spacer coupling allowing easier maintenance

- Additional bearings in pump head to share the strain of operation

- Inline ports, supplied flanged as standard

- Horizontal orientation

- Available with pressure relief valve

- Smaller footprint than an equivalent performing gear pump

- Low NPSH

- Suitable for lube and fuel oils from 2-1500cSt

- 230v, three phase 50Hz/60Hz motors available. IP55 as standard.

FAQs

Rather than having a mechanical seal to prevent liquid escaping from between the motor and pump shaft, magnetically coupled pumps use two magnets. The absence of mechanical seals that are prone to wear reduce the chance of leaking and maintenance.