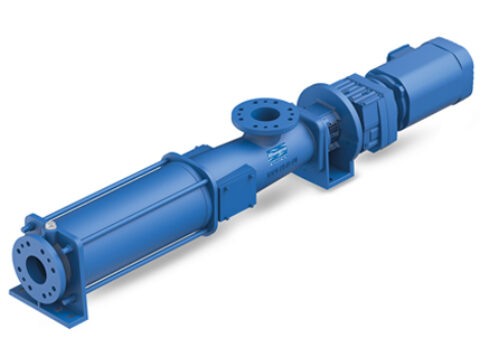

Progressive Cavity Pumps

Need help specifying the right progressive cavity pump? Contact our pump experts today!

Progressing Cavity Pumps For Those Difficult To Pump Fluids

Have you been told your fluid is a difficult one? Maybe it’s extremely viscous, full of large solids or barely even flowing? Then a progressive cavity pump is likely your solution. Progressive cavity pumps, also referred to as a helical rotor pump or an eccentric screw pump, are a design of pump characterised by their ability to handle high viscosity, solid laden and even pasty fluids, creams, gels, pastes and resins over long distances. Thanks to their smooth pulsation free operation, they are also ideal for shear sensitive fluids that can be damaged by other pumps. They are typically selected when other pump types will not be able to do the job due to fluid or pressure challenges. Our range of progressing cavity pumps include food grade options for use in the food, drink, cosmetic and pharmaceutical industries as well as options for installation direct into a drum or IBC for viscous fluid container emptying. If you have a challenging fluid and this sounds like a solution, contact our pump experts for technical advice to ensure you get the right model for your application.

products

- Max Flow Rate: 560M³H

- Max Head: 480M

- Max Temperature: 140 °C

- Max Viscosity: 200,000 cP

- Solids: 150mm

- Size: DN20 to DN100

- Max Flow Rate: 147M³H

- Max Head: 480M

- Max Temperature: 140°C

- Max Viscosity: 200,000 cP

- Solids: 95mm

- Size: DN20 to DN50

- Max Flow Rate: 80lpm

- Max Head: 150M

- Max Temperature: 100°C

- Max Viscosity: 80,000 cP

- Solids: 8mm

- Max Flow Rate: 80lpm

- Max Head: 150M

- Max Temperature: 100°C

- Max Viscosity: 80,000 cP

- Solids: 8mm

- Max Flow Rate: 80lpm

- Max Head: 150M

- Max Temperature: 100°C

- Max Viscosity: 100,000 cP

- Solids: 10mm

- Max Flow Rate: 80lpm

- Max Head: 15M

- Max Temperature: 100°C

- Max Viscosity: 100,000 cP

- Solids: 10mm

- Max Flow Rate: 80lpm

- Max Head: 15M

- Max Temperature: 100°C

- Max Viscosity: 100,000 cP

- Solids: 10mm

- Max Flow Rate: 50lpm

- Max Head: 80M

- Max Temperature: 120°C

- Max Viscosity: 80,000 cP

- Solids: 10mm

- Max Flow Rate: 50lpm

- Max Head: 80M

- Max Temperature: 120°C

- Max. Viscosity: 80,000 CP

- Solids: 10mm

- Max Flow Rate: 50lpm

- Max Head: 80M

- Max Temperature: 120°C

- Max Viscosity: 30,000 cP

- Solids: 8mm

- Max Flow Rate: 20lpm

- Max Head: 80M

- Max Temperature: 120°C

- Max Viscosity: 80,000 cP

- Solids: 10mm

- Max Flow Rate: 50lpm

- Max Head: 80M

- Max Temperature: 120°C

- Max Viscosity: 30,000 cP

- Solids: 8mm

FAQs

It consists of a spiralled helical rotor (like a cork screw) that sits tightly inside a rubber stator/sleeve. As the rotor turns inside the stator, it forms a set of fixed-shaped cavities that progress along the length of the stator and force the fluid inside to move along with them as they turn.

Their pressure capabilities and viscosity handling is unrivalled, which means that whilst they are quite expensive in design and large in footprint, they are often selected for applications when all other pumping technologies will fail.

The design is best suited to highly viscous and lubricating fluids including oils, sludges, waste matter, biomass, pastes and grape pressing that may contain very large solids, as well as pumping viscous products over long distances.

Yes! A progressive cavity pump's tight tolerances mean it has excellent suction capabilities.

Yes! However, it should be noted that abrasive fluids e.g. low viscosity/water based fluids containing solids may cause shorter stator wear. Therefore whilst large solids and high solid content can be handled, this is usually reserved for viscous, lubricating fluids.

Our progressing cavity pumps can be supplied with auger feed allowing non-flowing mediums such as dry sludge and waste matter to be pumped without clogging. We can also provide liquid injection ports which are popular when liquid waste is added to dry content waste to allow it to flow.

No! Even short period of dry running can result in damange to the rotor and stator, making dry run protection a must if there is risk of this.