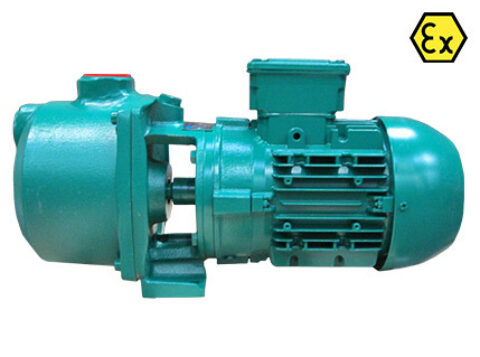

Close Coupled Centrifugal Pumps

Need help specifying the right centrifugal pump? Contact our pump experts today!

21 products

- Max Flow Rate: 300M³H

- Max Head: 105M

- Max Temperature: 130°C

- Max Viscosity: 200 cP

- Solids: 10mm

- Size: DN32 to DN150

- Max Flow Rate: 75M³H

- Max Head: 50M

- Max Temperature: 80°C

- Max Viscosity: 200 cP

- Solids: 0mm

- Size: DN25 to DN80

- Max Flow Rate: 500M³H

- Max Head: 100M

- Max Temperature: 120°C

- Max Viscosity: 200 cP

- Solids: 0mm

- Size: DN32 to DN150

- Max Flow Rate: 500M³H

- Max Head: 30M

- Max Temperature: 100°C

- Solids: 200mm

- Size: DN50 to DN200

- Max Flow Rate: 700M³H

- Max Head: 100M

- Max Temperature: 120°C

- Max Viscosity: 200 cP

- Solids: 0mm

- Size: DN50 to DN250

- Max Flow Rate: 1500M³H

- Max Head: 130M

- Max Temperature: 130°C

- Max Viscosity: 200 cP

- Solids: 0mm

- Size: DN50-250

- Max Flow Rate: 1250lpm

- Max Head: 38M

- Max Temperature: 95°C

- Max Viscosity: 500cP

- Solids: 9mm

- Size: 1" to 2"

- Max Flow Rate: 583lpm

- Max Head: 25M

- Max Temperature: 95°C

- Max Viscosity: 150cP

- Solids: 0mm

- Outlet Sizes: 1" to 2"

- Max Flow Rate: Up to 3M³H

- Max Head: 60M

- Max Temperature: 50°C

- Max Viscosity: 200 cP

- Solids: 0mm

- Size: DN25

- Max Flow Rate: 7.2M³H

- Max Head: 52M

- Max Temperature: 50°C

- Max Viscosity: 200 cP

- Solids: 0mm

- Size: DN25 to DN32

- Max Flow Rate: 12M³H

- Max Head: 66M

- Max Temperature: 80°C

- Max Viscosity: 200 cP

- Solids: 0mm

- Size: DN25 to DN32

- Max Flow Rate: 300M³H

- Max Head: 105M

- Max Temperature: 130°C

- Max Viscosity: 200 cP

- Solids: 10mm

- Size: DN32 to DN150

FAQs

A centrifugal pump transfers the kinetic energy of the motor to the liquid by a spinning impeller. As the impeller rotates, it draws in fluid causing increased velocity that moves the fluid to the discharge point.