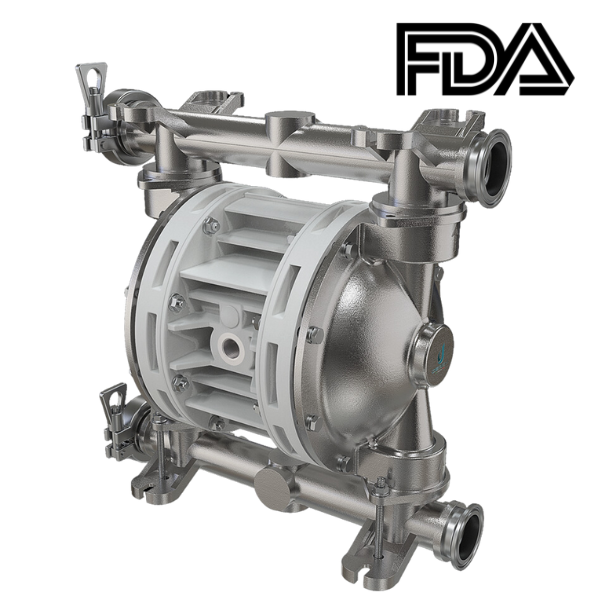

Food Grade Pumps

Discuss your food processing pump application with our experts today!

68 products

- Max Flow Rate: 900lpm

- Max Head: 55M

- Max Temperature: 100°C

- Max Viscosity: 100 cP

- Solid: 0mm

- Size: 1 1/4” to 3”

- Max Flow Rate: 140lpm

- Max Head: 22M

- Max Temperature: 130°C

- Max Viscosity: 100 cP

- Solids: 0mm

- Size: 1 1/4” to 1 1/2”

- Max Flow Rate: 45lpm

- Max Head: 240M

- Max Temperature: 150°C

- Max Viscosity: 1,000,000 cP

- Solids: 3mm

- Size: 3/8"

- Max Flow Rate: 11333lpm

- Max Head: 480M

- Max Temperature: 150°C

- Max Viscosity: 1,000,000 cP

- Solids: 30mm

- Sizes: 3/4" to 24"

- Max Flow Rate: 11333lpm

- Max Head (Pressure): 480M

- Max Temperature: 150°C

- Max Viscosity: 1,000,000 cP

- Solids: 30mm

- Sizes: 3/4" to 24"

- Max Flow Rate: 11333lpm

- Max Head: 480M

- Max Temperature: 150°C

- Max Viscosity: 1,000,000 cP

- Solids: 30mm

- Sizes: From 025 to 300

- Max Flow Rate: 147M³H

- Max Head: 480M

- Max Temperature: 140°C

- Max Viscosity: 200,000 cP

- Solids: 95mm

- Size: DN20 to DN50

- Max Flow Rate: 560M³H

- Max Head: 480M

- Max Temperature: 140 °C

- Max Viscosity: 200,000 cP

- Solids: 150mm

- Size: DN20 to DN100

FAQs

Pumps used for handling products for human consumption need to be food grade and are commonly constructed of stainless steel or other non-contaminating materials. Common types of food industry pumps include flexible impeller, peristaltic, lobe and AODD pumps.