The Types of Centrifugal Pumps

Centrifugal pumps are one of the most popular pumping solutions in the world due to their highly efficient and simple design, smooth flow, ease of operation and maintenance. Centrifugal pumps use one or more impellers that rotate synchronically with the pump shaft to increase the fluid’s pressure head and move it. Used in a range of industrial and marine applications, centrifugal pumps are suitable for pumping clean, low viscosity fluids such as water, fuel, oils and chemicals. This pumping solution is typically used for applications such as transferring general water supply, seawater transfer, boiler feed, water circulation and within chemical manufacturing. However, there are different types of centrifugal pumps, and each of them is best suited for specific applications. But what exactly are the differences, and when do you choose which? This article will cover just that and help you select the right centrifugal pump for your application.

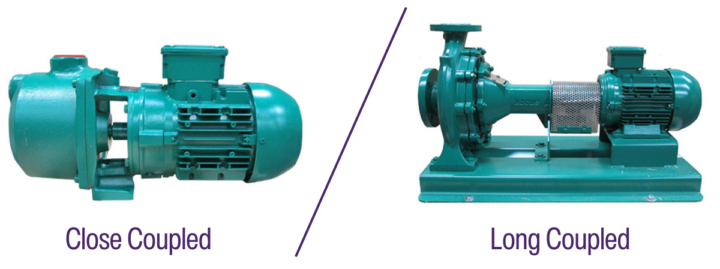

Close Coupled vs Long Coupled Centrifugal Pumps

There are several types of centrifugal pump, but first, we will focus on close and long coupled pumps as these are the two most common configurations. Centrifugal pump coupling is an important factor that needs to be considered when selecting a pumping solution as it directly affects efficiency, power and even pump maintenance.

There are several types of centrifugal pump, but first, we will focus on close and long coupled pumps as these are the two most common configurations. Centrifugal pump coupling is an important factor that needs to be considered when selecting a pumping solution as it directly affects efficiency, power and even pump maintenance.

Close-coupled centrifugal pumps do not require separate coupling as the motor is directly mounted to the pump. This makes this pump type very compact and more cost-effective than the long coupled centrifugal pumps. However, since there is only one set of bearings, the closed coupled pumps are less preferable for heavy-duty, high power applications as more strain is put on the bearings, and the size of the motor is usually limited. Therefore, for heavy-duty and continuous use applications such as water circulation and cooling, long-coupled pumps are more suited. The long coupled centrifugal pump design allows the pump and motor to be mounted on their own shafts separated by a coupling. This way, the separate bearings share the strain of operation, extending the lifespan of the mechanical parts. In addition, long coupled centrifugal pumps have a large space between the head and the motor, meaning if the seals wear, the fluid won’t leak and damage the motor.

In conclusion, although close coupled centrifugal pumps are reliable solutions, they are typically selected for less heavy-duty applications and where a cost-effective and compact pump is needed.

Vertical Inline Pumps vs Horizontal Pumps

When selecting a pump based on being horizontal or vertical, it all comes down to convenience and application requirements. Both types of centrifugal pumps have their own advantages that you need to keep in mind, but their working principles are similar.

The main difference between horizontal and vertical centrifugal pumps is the shaft’s position. Horizontal centrifugal pumps typically have their shaft placed horizontally, between the bearings or overhung, and vertical inline pumps have a vertical shaft, meaning the design of the shaft is radial split and overhung. This distinctive pump characteristic is important when installing and fitting the pump to the existing pipework.

Another key difference that you need to keep in mind is pump maintenance. Compact vertical centrifugal pumps are difficult to repair and maintain, as their design requires the pump to be lifted every time it needs to be repaired. Therefore, vertical inline pumps are typically selected for specific applications and where space is an issue.

On the other hand, horizontal pumps are more commonly used because they are easy to maintain and install. Also, they provide easy access to the internal parts and can be coupled securely with external accessories such as turbines and electric motors. However, this pump type takes up a larger footprint, and their working temperature and pressure are lower than vertical centrifugal pumps.

Magnetic Drive Pumps vs Mechanically Sealed Centrifugal Pumps

Centrifugal pumps also can be divided into two main groups: mechanically sealed pumps and seal-less magnetic drive pumps. The main difference between these two centrifugal pumping solutions is that mechanically sealed pumps have seals that prevent the pump fluid from leaking, and magnetically coupled pumps use two sets of magnets, meaning no seals are needed, and the risk of leakage is eliminated.

This design difference makes magnetic drive pumps an ideal solution when handling hazardous, corrosive, flammable and/or explosive fluids and other toxic chemicals. Being magnetically coupled, these centrifugal pumps also benefit from a lack of friction loss, wear and noise, meaning they provide cost-effective maintenance and efficient pump operation. Although magnetic drive pumps are reliable pumping solutions, there are some design limitations that make mechanically sealed centrifugal pumps more suitable for specific applications.

Mechanically sealed pumps are more powerful and can operate in extreme conditions due to their firm connection. In addition, centrifugal pumps with mechanic seals are better in handling solids, high-temperature fluids and even dry running. This means that both centrifugal pump types are best suited for specific applications. For example, magnetically coupled centrifugal pumps are commonly used in the chemical industry as they are ideal for transferring hazardous/dangerous fluids. On the other hand, mechanically sealed pumps are the preferred pumping solution for industrial and marine applications such as food and beverage processing, seawater transfer, aquaculture etc.

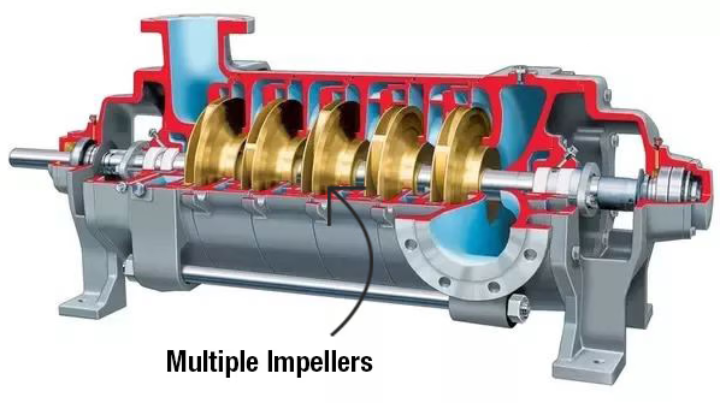

Single Stage vs Multistage Pumps

Based on the number of impellers, centrifugal pumps can be divided into single stage and multistage pumps. Although the primary difference is their impellers, this greatly affects the pump’s operation and efficiency.

The multistage centrifugal pump has multiple impellers that are installed and rotated on the same shaft, and as the flow progresses from one impeller to the next, the head increases by the same amount, resulting in achieving much higher pressure capabilities than a single impeller. This means that multistage centrifugal pumps are typically selected for applications where high-pressure capabilities are required, such as transferring fluids that must be moved over a very large distance. On the other hand, single-stage centrifugal pumps have a simple structure, stable operation, high efficiency and large flow capacity. They are designed for applications where a large flow rate is more important than pressure capabilities. Also, single-stage centrifugal pumps are one of the most popular centrifugal pump designs, meaning they can be supplied in various materials and design variations to meet specific application requirements. Ideal for applications that require the pump to deal with large volumes such as general water transfer and ballast water pumping, single stage pumps are highly reliable and low maintenance solutions.

Vertical Immersion Pumps

Vertical immersion pumps are centrifugal pumps with an elongated shaft that separate the motor from the pump. Although the pump impellers are immersed in the fluid, the pump motor stays outside the fluid due to the long vertical shaft design. This unique pump design brings several distinct advantages and makes this pumping solution ideal for emptying wells, sumps, reservoirs and tanks.

The beauty of vertical immersion centrifugal pumps is that they can handle high temperature and potentially explosive fluids like petrol and certain chemicals because their seals and motor are situated outside of the fluid, meaning there is no risk of high temperature degrading the pump seals and hazardous fluids damaging the motor. In addition, the pump's flooded suction design eliminates the risk of cavitation caused by the NPSH, and the separated pump motor makes this centrifugal pump type a lot easier for maintenance than standard submersible pumps.

Like vertical centrifugal pumps, vertical immersion pumps have a compact space-saving design ideal for installations where space is an issue.

Do you need a centrifugal pump?

Do you have a particular application in mind and aren’t sure which centrifugal pump you need? Discuss with our pump experts today!