The Importance of Low Shear Pumps When Handling Delicate Fluids

Are you pumping a shear sensitive fluid? Does your manufacturing process involve a liquid that alters when heavy force like stirring is applied? This article will give you more of an insight into exactly what a shear sensitive product is and how this impacts pump selection if your application involves handling one. So, let’s start with a deeper look at the characteristics of a shear sensitive liquid…

What are shear sensitive fluids?

Shear sensitive liquids are those that become altered or even damaged when force is applied. In the most simplistic of terms, they are delicate fluids that change viscosity when “messed with” like shampoo turning into foam, or that contains solids that can be crushed but for the purpose of their use should not be, like fruit pieces in a yoghurt.

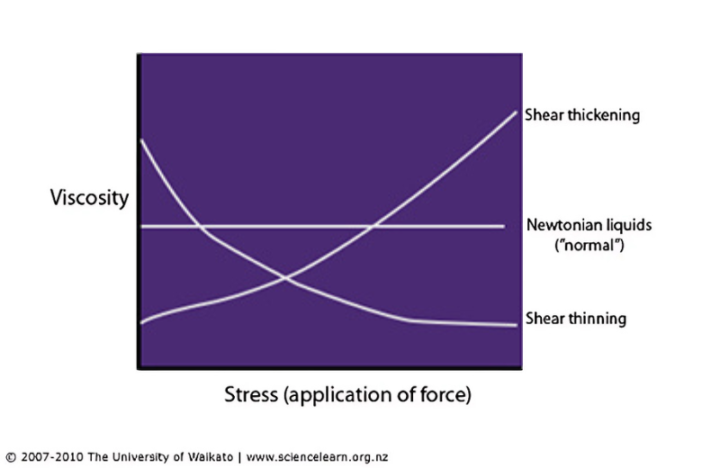

In more scientific of explanations, all liquids can be categorised into either Newtonian or non-Newtonian. Newtonian fluids are those that remain at a constant viscosity no matter the amount of shear applied (providing temperature remains the same). These include water, alcohol and mineral oil.

With non-Newtonian fluids, how thick or thin the liquid is can alter depending on the composition of the product and how it reacts to shear being applied. The way the liquid reacts can be identified in four ways - Dilatant (Shear Thickening), Pseudoplastic (Shear Thinning), Rheopectic and Thixotropic.

- Dilant - become much thicker when force is applied - think of a cornflour and water mixture.

- Pseudoplastic - are the exact opposite, with them become less viscous with increased stress - just like tomato sauce!

- Rheopectric – become more viscous as more stress is applied over time – if you whip cream for long enough, it becomes much thicker.

- Thixotropic – becomes less viscous as more stress is applied over time – if you stir honey over a period of time it becomes much more fluid.

But why does this impact pump selection and what exactly is a shear sensitive pump?

What is a low shear pump?

Whilst certain pumping technologies such as centrifugal pumps apply high shear in operation, shear sensitive pump designs are able to keep such fluids intact due to their low internal velocity, gentle pumping mechanism and the wider tolerances between their pump casing and internal components. Failing to select a low shear pump when handling a shear sensitive liquid can result in product inconsistencies, damaged solids that need to be intact and costly waste.

To demonstrate the importance of using a shear sensitive pump technology that doesn’t damage your delicate fluid, we filmed us testing a higher shear pump on shampoo to show that the result was it turning to foam, which of course can’t be bottled and sold to a customer!

Typical low shear pump types are typically positive displacement pumps and include peristaltic pumps, progressive cavity pumps, flexible impeller pumps and air operated diaphragm pumps (AODD pumps).

Low shear centrifugal pumps – do they exist?

No! Centrifugal pumps are not a type of low shear pump. They apply high shear levels during operation due to the fast speed at which their impeller/s spins causing high velocity and turbulence within the liquid. Pumps used for shear sensitive fluids are usually positive displacement pumps due to their low internal velocity, wide tolerances and gentle pumping.

Does your process involve the handling of a shear sensitive fluid that you cannot risk altering or damaging? If so, you can now see the importance in using a shear sensitive pump within your installation.

Looking for a new pump for your shear sensitive fluid?

Discuss your shear sensitive application with our pump experts today if you are handling delicate and easily altered fluids.