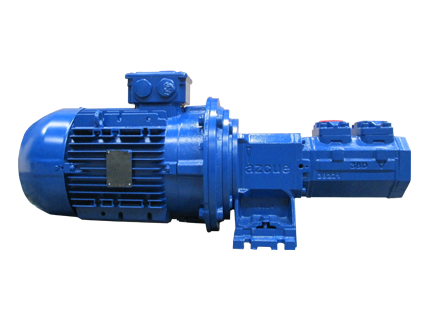

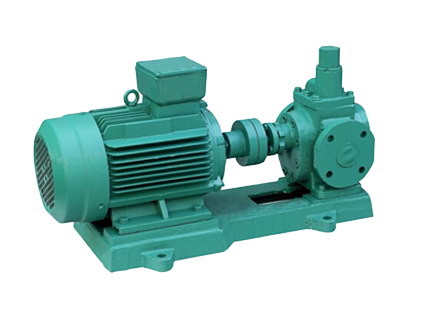

Screw Pumps vs Gear Pumps

For applications involving the transfer of fuels, oils and other lubricating fluids, screw pumps and gear pumps are usually the pumping technology selected. Unlike water based liquids, changes in the temperature often result in a change in the viscosity of these types of fluids. As fluctuations in the thickness of a fluid affects the performance of a centrifugal pump much more than a positive displacement pump, screw pumps and gear pumps are generally the most efficient solutions for oils and fuels.

Whilst a gear pump is a more than acceptable option for the handling of lubricating fluids, the design of the screw pump has several advantages over it. To make these features as clear as possible, we have constructed a comparison table below.

| Screw Pumps | Gear Pumps |

|---|---|

|  |

| Screw pumps have a better suction capability and therefore work much better in a long pipeline, for more viscous oils and when air is present in the fluid. | A gear pump's suction capacity is usually less than an equivalent screw pump, making it less efficient under difficult suction. |

| The screw elements inside the pump have a smaller diameter than gears (for the same capacity), producing less turbulence in the fluid for smoother pumping. | Gears need a large diameter for the requested capacity and therefore produce more pulsations in the fluid discharge. |

| Screw pumps are able to work at a higher motor speed (3000-3500 RPM). | Due to the larger gears, rotation speed is limited. If you increase the RPM, the pump loses suction. |

| The screw pump design has better mechanical efficiency as it uses less power for the same capacity relative to a gear pump, thus saving energy costs. | The motor in gear pumps use higher power for the same capacity as a screw pump, resulting in increased energy costs and a larger motor required. |

| The operation of a screw pump is much softer with less pulsations, less noise and fewer vibrations, meaning longer lifespan. | Gear pumps are noisier, more turbulent and cause more vibrations for the pump and pipework to withstand causing a lower working life. |

| Screw pumps typically have a smaller footprint, making them better when space is an issue. | As they generally have a larger footprint, they aren't as good for installations where room is limited. |

| Internal components such as the screws generally need to be replaced at the same time to ensure efficient operation, making them quite expensive to maintain. | Internal components are often cheaper than those in a screw pump, however as bushes and bearings are in the pumped liquid they are more subject to wear. |

Sometimes customers insist on gear pumps, often because that's what they know. We typically supply gear pumps for industrial fuel and oil applications where budget is not as high, but for marine applications we tend to offer a screw pump. Popular applications include:

- Handling diesel and fuel oil

- Lube oil transfer

- Circulating lubricants in a closed system

- Fuel oil separating

- Oil burner/boiler boosting

Are you looking for a screw pump?

If you have an application involving the transfer of fuels, oils or lubricants, then take a look at our full range of screw pump models.