Pressed Metals vs Cast Metals

Pumps are available in a wide variety of materials and finishes but one of the most distinct differences in pump construction is that some parts and casings are manufactured from cast metal and others are made from pressed metals. There are big differences between cast and pressed metals, but what are these differences? How do they affect the decision on which pump is best for the process, as well as having the lowest lifetime cost?

So, What's The Difference?

Metal pumps can be manufactured using either cast or pressed metals, the main difference being the process in which these metals are shaped.

Pressed metal pumps are manufactured from sheet metal through a forming process. This process changes the shape of the sheet metal into that of the required object. The sheet metal is then cut to size from the required piece, and is then pressed into shape using either hot or cold force. Any fittings which are required such as flanges and screwed connections are welded to the casing. A pump casing can be a combination of between 2-5 separate pieces which are welded to the casing, with the welds being a few mm thick.

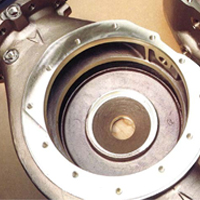

Cast metals on the other hand, are often manufactured from molten ferrous and non-ferrous metals through sand casting, lost foam/wax, or investment casting. Additives can be incorporated during casting to create variations of metals; such as magnesium to cast iron – to create ductile iron (spheroidal graphite), or aluminium to copper – to create aluminium bronze. Cast pumps are essentially a single piece of metal without welded parts. Not only is the body cast, but also the internal parts such as impellers and wear rings are cast or machined from a solid bar.

| Cast Metals | Pressed Metals |

|---|---|

|  |

| Available in a wide range of materials, ensuring compatibility with a larger range of applications. | Not available in the same number of alloys, as some metals are unsuitable for pressing due to their micro-structure not allowing them to be worked mechanically. |

| Rugged design due to thick casing casing moulds. Also have a good rigidity to pipe loads, reducing coupling and bearing misalignment. | Sheet metal is usually only a few mm thick, making them much more susceptible to damage when knocked. |

| Good solid handling capabilities due to the robustness and thickness of the casing and impellers. | Don't handle solids as well, so are preferred for the transfer of clean liquids. |

| Allow the use of easily replaceable wear rings, which not only wear instead of the more costly casing, but also improve pump efficiency. | Do not use wear rings, meaning that the casing which is only a few mm thick wears quite quickly, hence their lower operating lifespan. |

| Have an allowance for corrosion within the casing. | Usually laser welded using a filler metal which typically degrades quicker than the casing, and often corrodes when in contact with salt water or chemicals. |

| Designed to withstand high pressures and radial loads are easily manufactured. | Not designed for high pressure applications. |

| Easy recyclable as they can be dropped back into a cupola (casting pot) at the end of their life. | After the initial shape has been cut from the sheet, there are leftover pieces too small to make parts from. These would need to be taken to a recycling centre. |

| More expensive initially, with lower overall lifetime cost. | Smaller initial outlay, with higher overall lifetime cost. |

Which Should I Choose?

Sometimes, the specification of the pump is simply not possible with pressed metals due their design limitations. For example, pumps for high pressure applications or where they require an overhung bearing design.

It is true that typically, pumps constructed in cast metals are likely to be a more expensive initial cost, so pressed metal pumps are usually considered when budget is tight. However, for many of the reasons stated above, they represent the best value of money over their total lifetime due to their durability of design, ruggedness and thickness. As a pump supplier, we would always recommend selecting cast metal pumps over pressed pumps where it is an option to do so.

Need help choosing the RIGHT pump?

Our technical sales engineers are available to talk through your process requirements and specify the model you need.