Positive Displacement vs Centrifugal Pumps

There are two main families of pumps; positive displacement and centrifugal (rotodynamic), both of which have their uses and best areas of application. It is important however to be able to identify when each pump type should be selected, which ultimately comes down to their working principle and the application at hand.

Positive displacement pumps are characterised by an operation that moves fluid by trapping a fixed volume, usually in a cavity, and then forces that trapped fluid into the discharge pipe. A centrifugal pump transfers the kinetic energy of the motor to the liquid by a spinning impeller; as the impeller rotates it draws in fluid causing increased velocity that moves the fluid to the discharge point.

A quick comparison table

Below is a quick comparison table that highlights the main performance differences between centrifugal (rotodynamic) pumps and positive displacement pumps.

| Factor | Centrifugal | Positive Displacement |

|---|---|---|

| Mechanics | Impellers pass on velocity from the motor to the liquid which helps move the fluid to the discharge port (produces flow by creating pressure). | Traps confined amounts of liquid and forces it from the suction to the discharge port (produces pressure by creating flow). |

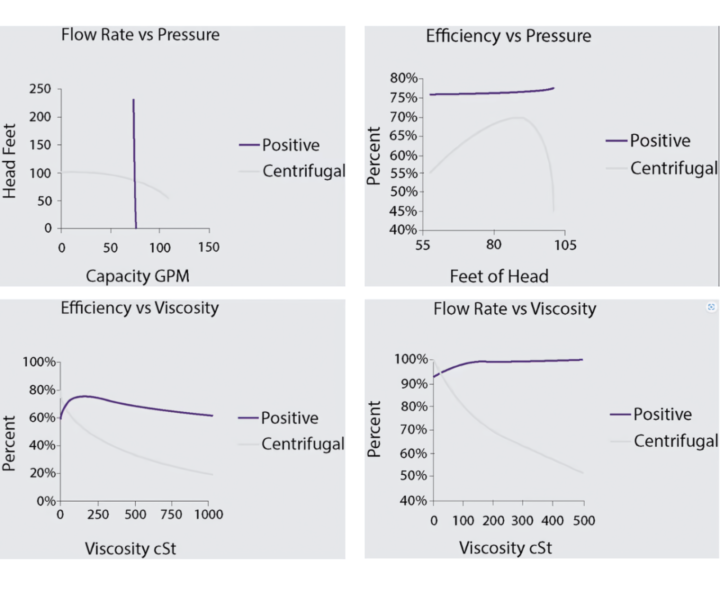

| Performance | Flow rate varies with a change in pressure. | Flow rate remains constant with a change in pressure. |

| Viscosity | Flow rate rapidly decreases with increasing viscosity, even any moderate thickness, due to frictional losses inside the pump. | Due to the internal clearances high viscosities are handled easily and flow rate increases with increasing viscosity. |

| Efficiency | Efficiency peaks at a specific pressure; any variations decrease efficiency dramatically. Does not operate well when run off the middle of the curve; can cause damage and cavitation. | Efficiency is less affected by pressure, but if anything tends to increase as pressure increases. Can be run at any point on their curve without damage or efficiency loss. |

| Suction Lift | Standard models cannot create suction lift, although self-priming designs are available and manometric suction lift is possible through a non return valve on the suction line. | Create a vacuum on the inlet side, making them capable of creating suction lift. |

| Shearing | High speed motor leads to shearing of liquids. Not good for shear sensitive mediums. | Low internal velocity means little shear is applied to the pumped medium. Ideal for shear sensitive fluids. |

What applications are centrifugal pumps used for?

Centrifugal pumps are the most common pump type for the transfer of low viscosity fluids in high flow rate, low pressure installations, which makes them ideal for applications that require the pump to deal with large volumes. The centrifugal pump design is often associated with the transfer of water, but is also a popular solution for handling thin fuels and chemicals:

- General water supply

- Sea water transfer

- Water circulation

- Air conditioning

- Boiler feed

- Light fuel transfer

- Petrochemical

- Washing and firefighting

- Irrigation

Whilst generally speaking centrifugal pumps are used with clean liquids, if the correct impeller is selected i.e. a vortex impeller, some solids are able to be handled.

Centrifugal pumps benefit from a simple design with few moving parts, resulting in lower maintenance requirements and costs. This makes them suited to applications where the pump is used often or is even continuously run. The simplicity of the construction also makes centrifugal pumps easy to produce in many different materials including plastics and cast iron for lighter duties, and bronze and stainless steels for more corrosive or hygienic application. Hence the multiple fluids that centrifugal pumps are suitable for use with.

The centrifugal pump design is also very compact in comparison to other pump types that produce the same output levels, making them a good option when space saving is an issue.

When to use a positive displacement pump?

Positive displacement pumps are usually selected for their ability to handle high viscosity fluids at high pressures and relatively low flows as their efficiency isn’t affected by pressure. Whilst centrifugal pumps are the most common type of pump installed due to their simplicity, positive displacement pumps are a solution that can handle more difficult conditions where centrifugal pumps may fail, thanks to their ability to be run at any point on their curve.

There are two classifications of positive displacement pump; rotary and reciprocating. Whilst governed by the same working principle, all pumps types that fall within these classifications have their own design characteristics and benefits.

Rotary positive displacement pumps – operate via rotation of the pumping element

Reciprocating positive displacement pumps – operate via a constant back and forth motion.

Generally speaking positive displacement pumps are designed for the transfer of high viscosity fluids such as thick oils, slurries, sewage and pastes. Thanks to their internal clearances, some types such as progressive cavity pumps and peristaltic pumps, are also excellent at applications handling mediums containing high levels of solids including dewatering ground water and waste oils. Screw and vane pumps on the other hand and are ideal for pumping relatively clean fluids such as fuels and lubrication oils.

Being lower speed pumps than the centrifugal design, rotary positive displacement pumps with larger pumping chambers such as progressive cavity, lobe and peristaltic pumps are typically low shear pumps that provide a smooth flow. This allows them to pump shear sensitive products that need their structure to remain intact such as olives that cannot be squashed and adhesives that cannot lose their stickiness and gels that need to retain their gel-like property.

Positive displacement pumps are able to handle variations in pressure, flow and viscosity and remain efficient, unlike centrifugal pumps which do not operate well off the centre of their curve. As their flow rate remains constant (proportional to the speed of operation), smooth and low pulsating despite changes in the pressure, positive displacement pumps such as peristaltic, piston and diaphragm pumps are ideal solutions for dosing applications as it allows accurate metering to be carried out.

As this guide illustrates, some processes are suited to centrifugal pumps and others to positive displacement pumps. What is important to note is the application conditions that make one more suitable than the other.

Still unsure what pump you need?

Do you have a particular application in mind & aren’t sure whether it's a positive displacement or centrifugal pump you need?