Multistage Pump Guide

Due to their relative simplicity of design, centrifugal pumps are the most common pump type in the market. Centrifugal pumps are categorised into either single or multistage pumps, both of which have their uses. What is important to understand is where which should be selected, which ultimately comes down to their working principle and the application in question. So, let’s understand the differences between the two…

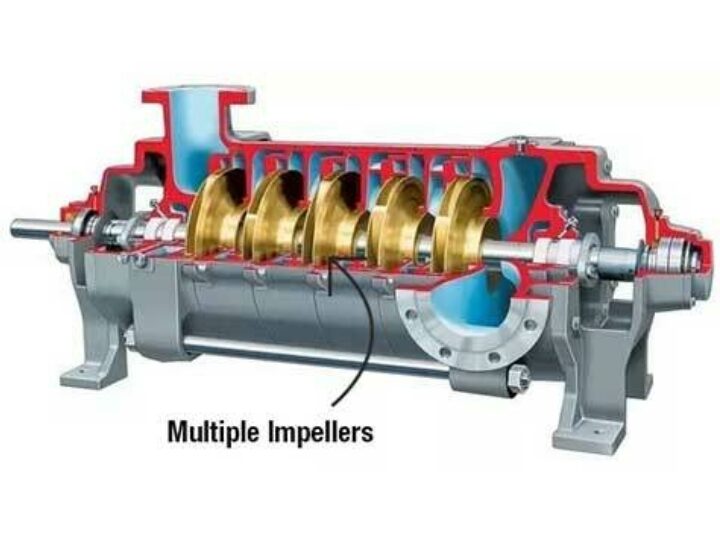

The primary difference between single and multistage pumps is their impellers and how this affects operation. Whereas a single stage pump has only one impeller rotating around the shaft, multistage pumps have two or more. This characteristic has several implications for the performance of the pump, which we will go onto now.

What is the difference between single and multistage pumps?

1. Pressure capabilities

The multiple impellers of a multistage centrifugal pump are all installed and rotated on the same shaft, and essentially act like separate pumps. This mean that as the flow progresses from one stage to the next, the head increases approximately by the same amount, resulting in the multistage pump design having much higher pressure capabilities than a single impeller is able to alone.

With the above in mind, multistage centrifugal pumps are often selected when the pressure requirements of the application exceed the capabilities of a single stage pump. For example, perhaps the fluid must be moved over a very large distance with considerable friction loss, which in most scenarios is achieved via multiple impellers. A typical example of this may be providing water supply to the top of tall buildings or towers. Single stage centrifugal pumps are on the other hand the better suited solution in higher flow, lower pressure installations.

2. Efficiency

As multistage pumps reply on multiple impellers used to impart energy into the fluid being handed, each impeller can be smaller in diameter than it would be alone and can operate with tighter clearances between the impeller and volute. These smaller tolerances mean that each impeller operates closely to its best hydraulic efficiency. The result of this is that multistage centrifugal pumps are able to achieve higher performance with a smaller motor size and using less energy.

Typical applications of a multistage centrifugal pump

Due to the tight impeller clearance with the pump volute, multistage pumps are unable to handle solids and abrasive content unless they are oversized, which is why they are generally used with water and other low viscosity fluids. This combined with their high pressure range, makes multistage water pumps popular in applications including:

- Boiler feed

- Reverse osmosis

- Water supply boosting

- Irrigation

- Fire fighting

- Heating/cooling conditioning

- Water circulation

Does this sound like what you need?

If from reading the above it sounds as though a multistage centrifugal is indeed what you are looking for, take a look at our range of pumps.