Cooling Pumps

Cooling is the process whereby unwanted heat is removed from machinery including engines, gear boxes, turbines and winches, or to generally cool a building. Whilst glycol and brine can also be used, many cooling pump applications use water (fresh or seawater) as the method of absorbing heat due its high boiling point and it being so readily available, at a relatively low cost. To understand the part that cooling pumps play in a system, let's take a look at the different methods of cooling…

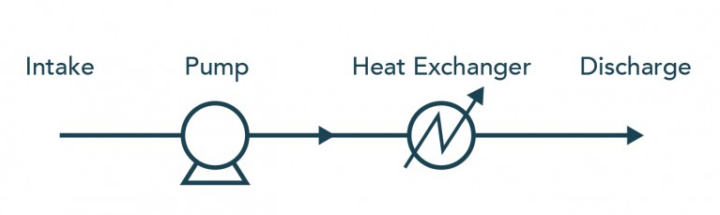

Once-Through Cooling Systems

As its name suggests, a once-through cooling system is where cool water is pumped from a water source, passed through the circuit to absorb the heat just once before being discharged back into the original source as now warmer water.

This design is relatively simple and inexpensive to install, typically used when equipment is located near a source of low cost, accessible water. Whilst previously the most popular solution, once-through cooling is less favourable for new installations due to the ecological issues of returning potentially contaminated, warm water back to its source.

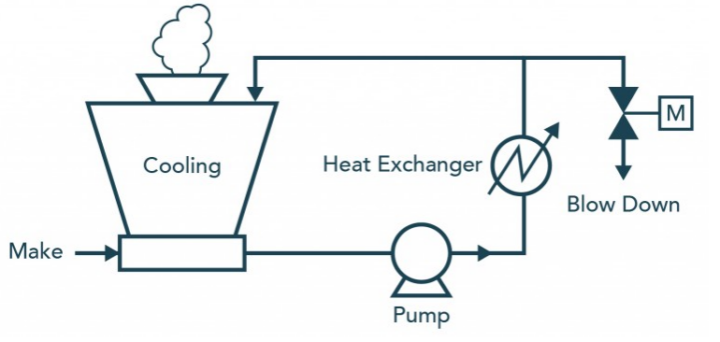

Recirculating Cooling Systems

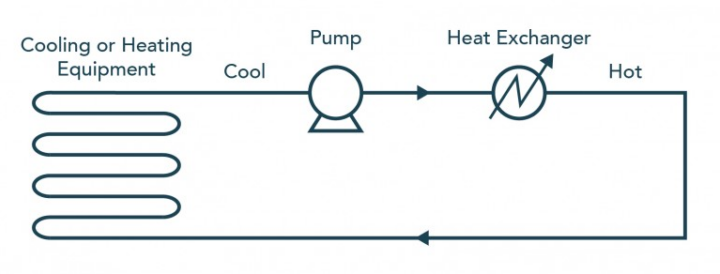

Here, rather than being returned to its original source after use, the water is recirculated throughout the system to be used over and over again using a water circulating pump. A recirculating cooling circuit can be categorised into open or closed-loop systems.

Often, open-loop systems make use of a cooling tower; open-air container tanks, to expose water to the environment after it is used. Water from the heat exchanger is pumped over the top of the cooling tower and as it flows down, the air cools the water back to its original temperature. The now cool water is collected at the basin of the tower, minus any water that has evaporated, ready for the cooling tower pump to transfer it back into the heat exchanger and recirculated around the cooling system.

In the opposite way, closed loop systems keep the water within the pipework of the system, avoiding any contact with the environment. They work by a closed-loop cooling pump moving the primary coolant fluid to a heat exchanger where the heat from the system is absorbed, which is then transferred to a second coolant in a secondary exchanger, making the primary fluid cool enough again to be reused.

Cooling Water Pump Applications

In industrial environments, cooling is a critical process to ensure that equipment and systems do not overheat. For that reason, cooling pumps are often supplied in duty/standby configuration with a second pump providing backup to the main pump should it need maintaining or worst case, it fails.

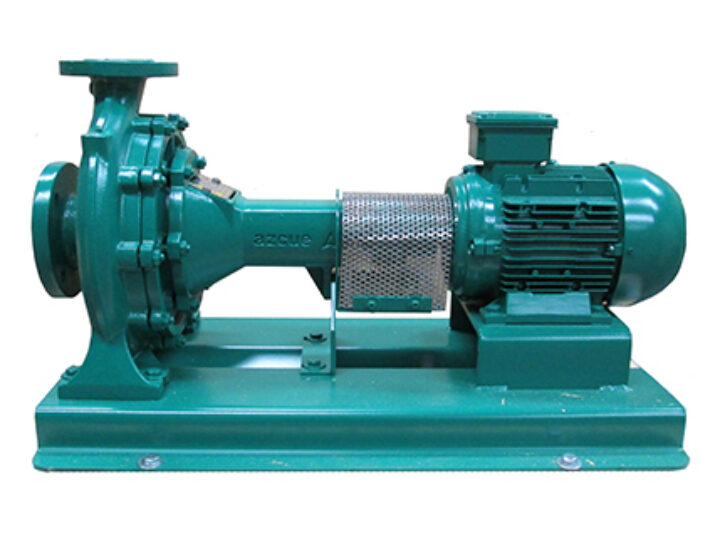

Cooling water pumps are often required to run continuously, meaning that they need to be extremely durable and are often supplied with larger, 4 pole motors running at half speed to reduce wear. For the most industrial of applications, long coupled pumps are usually supplied as it reduces the risk of any fluid entering the motor in the event of a mechanical seal failure.

Centrifugal pumps are usually the choice for cooling pumps due to their efficiency when it comes to handling low viscosity fluids such as water. Whilst cooling systems have that similarity, the specific application at hand does mean that there are some differences to the specification of the pump supplied.

- Power Plant – This is one of the easiest to picture examples, as everyone has seen the large cooling towers outside a power plant. Higher flow, low head centrifugal pumps are usually used for the high volumes of water transfer into the cooling towers.

- Marine Engine – Cooling of the engine is a vital process for the safety and operation of a vessel. Modern ships usually utilise a closed-cooling system, whereby fresh water is used to cool the engine directly, and then the seawater is used to cool the freshwater in the secondary exchanger. This system means that only the seawater cooling pump needs to be manufactured in more costly materials such as bronze or stainless steel that are compatible with the corrosive salt content.

- Manufacturing/Process – Cooling of engines and gearboxes used in production lines, lifting equipment and any other large equipment that is in near-continuous operation.

- HVAC – Unlike the other examples concerning machinery, HVAC cooling installations are designed to provide comfort to people, for example in hospitals, schools and large commercial buildings. Such cooling water pumps are typically low head and low flow single-stage centrifugal as they tend to be smaller systems than industrial cooling.

In need of a cooling pump?

Our range of water cooling pumps includes vertical immersion, vertical inline, long coupled, close coupled and more. View our range or get in contact to discuss your individual requirements.