Technical Information & Guides

7 Ways to Improve the Energy Efficiency of Your Pump

The environmental impact of activities, products and services is measured and monitored now more than ever, especially within the marine and industrial markets. This along with the ever increasing need to reduce costs, means energy efficiency is an important factor - especially where your pumping system is concerned. In this article we discuss 7 ways that you can improve the energy efficiency of your pump...

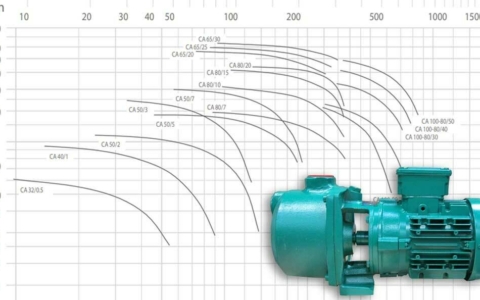

How To Read the Pump Curve of a Centrifugal Pump

Pump curves are essential during the decision making process, as they provide the information you need in order to see whether the pump will perform how you need it to! In their most basic form, performance curves contain flow rate and pressure data. Being able to read a pump curve enables you to choose the right pump, rather than choosing one that could potentially cause damage, consume unnecessary energy or perform poorly.

How to Calculate Head Loss in a Pumping System

Head loss is an essential part of the preparation of looking for a pump with specific requirements. These head losses - also known as pressure losses - are sustained by the fluid as it flows through the pump and therefore can affect the pumping operation. Being such an important factor when making the decision on which pump to purchase, we have created this section for you to calculate the head loss within your application.

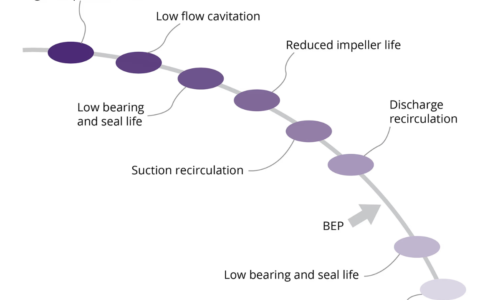

Best Efficiency Point of a Centrifugal Pump

If you operate, maintain or specify centrifugal pumps then you will likely have heard of a pump curve. However, what many misses to consider is the best efficiency point of the pump they are selecting, which can result in costly maintenance and downtime. So, read this article and learn more about what BEP is and what happens to your pump when you operate it too far left/right of the pump curve.

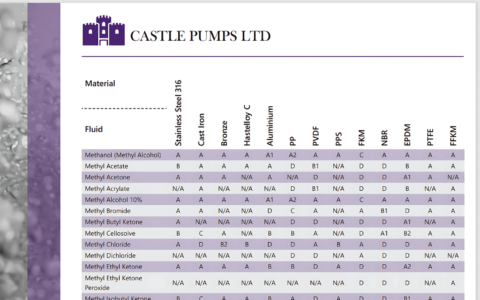

The Importance of Chemical Compatibility

Ever wondered why you can't just have a pump that's suitable for all fluids? Well this article will explain why, and it's all down to chemical compatibility! One of the first questions you'll be asked when sourcing a pump, fitting or pipework is 'what fluid are you handling?', and this is because the fluid will determine what material the pump needs to be made of to avoid corrosion, damage and failures!

Fluid Compatibility Guide

Doing a fluid compatibility check when sourcing a pump is one of the first things you need to think about! Certain fluid/material combinations can result in corrosion, swelling, brittleness, leaking and even the dissolving of the pump! So ensuring you have the right pump material for the fluid you want, is a must! This fluid compatibility table will give you the information you need to determine which material will suit your fluid best.