Technical Information & Guides

Pump Term Glossary

NPSH, Total Dynamic Head and Best Efficiency Point are just some of the terminologies used during the pump selection process, but do you what they mean? Technical jargon can sometimes leave your head in a bit of spin, so if you want to learn the lingo and understand what these words mean, let us guide you through 27 terms that you're likely to come across when buying a pump!

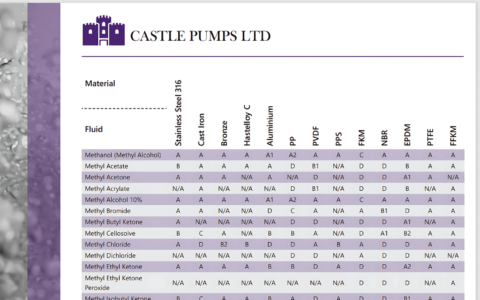

Fluid Compatibility Guide

Doing a fluid compatibility check when sourcing a pump is one of the first things you need to think about! Certain fluid/material combinations can result in corrosion, swelling, brittleness, leaking and even the dissolving of the pump! So ensuring you have the right pump material for the fluid you want, is a must! This fluid compatibility table will give you the information you need to determine which material will suit your fluid best.

Why Viscosity is Critical to Pump Selection

When specifying a pump for oil, we'll need to check what type of oil you'll be pumping. Viscosity is critical for pump selection, and with so many different types of oil it's no surprise that the range of viscosity can vary from oil to oil. Confirming the viscosity of the pumped medium will put you on track to getting the right pump for your application, and this article will explain in depth why knowing the viscosity is so important!

The Importance of Chemical Compatibility

Ever wondered why you can't just have a pump that's suitable for all fluids? Well this article will explain why, and it's all down to chemical compatibility! One of the first questions you'll be asked when sourcing a pump, fitting or pipework is 'what fluid are you handling?', and this is because the fluid will determine what material the pump needs to be made of to avoid corrosion, damage and failures!

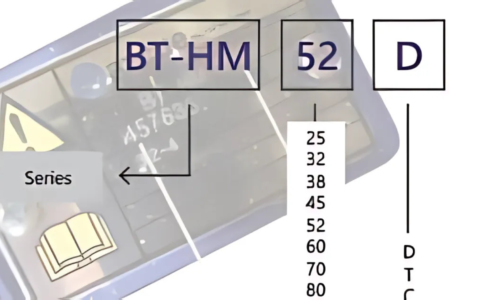

The Guide to Understanding Azcue Pump Model Numbers

A pump name plate and the letters and numbers on it can tell you a lot about a pump (if you know what to look for)! A combination of two letters will give you the pump type and a further two letters will let you know if an additional priming pump is present. Following this are a selection of numbers and letters and these will give you an insight into the pumps specifications. Find out more in this handy guide.

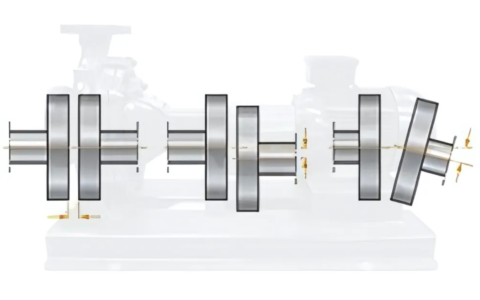

Pump Couplings – A Comparison of Rigid, Flexible & Magnetic

Understanding pump couplings - a complete guide. In this article we discuss everything you need to know about couplings; from what a coupling is, to the three different types available and the performance of each type. We also talk about the issue of misalignment, a factor which should always be considered when deciding which coupling is the right one for your application.