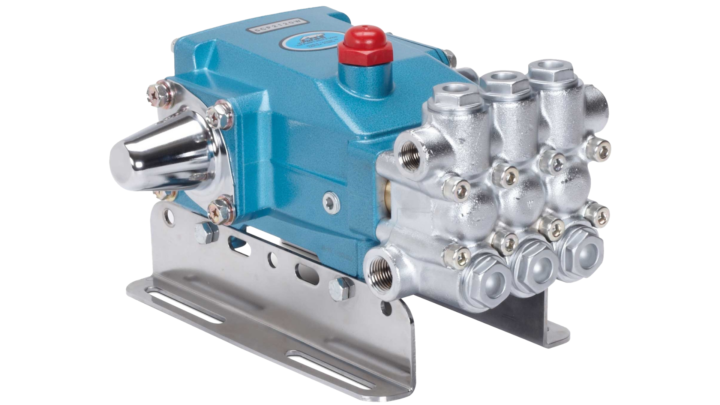

CAT Pump Spare Parts & Maintenance

If you have a process that relies on a CAT pump, you will know that maintenance is vital to the efficient, long life performance they are built to offer. CAT pumps are a widely respected brand thanks to their quality, robust performance, but like any mechanical item, overtime parts wear and need replacing with genuine CAT pump spares to ensure continued operation without costly downtime to the user.

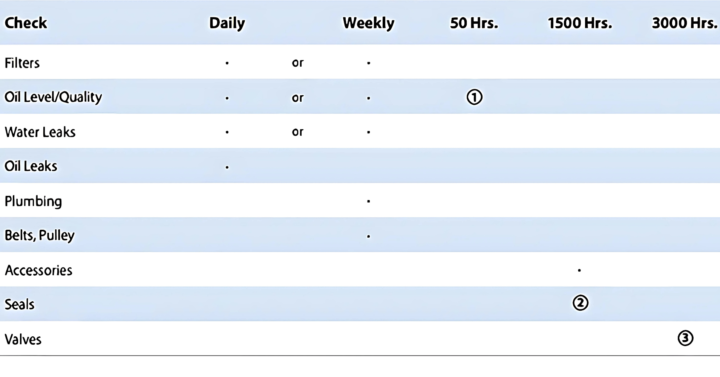

To help pump owners, CAT Pumps have devised a typical CAT pump maintenance schedule that include when to change certain wearing CAT pump spares. Whilst, maintenance intervals will differ depending upon the specific operating conditions including duty cycle, performance, fluid temperature and application environment, this is a usual indication of when checks should be undertaken. If however, you notice the pump performance degrade or change, you should check oil, seals and valves immediately.

1. Oil Level/Quality

It is recommended that after initially installing your CAT pump, that the oil is changed after the first 50 hours of operation, and then either every 3 months or every 500 hours thereafter, whichever is sooner. CAT Pumps recommend using their official custom-blend premium grade ISO 68 hydraulic oil.

My pump is leaking oil, what should I do?

If you spot an oil leak, it is important to first determine the source and then act. If your CAT pump oil is leaking from the oil cap, then simply the oil level is too high, so you should drain it until the level is at the centre of the bubble gauge. If the leak is coming from between the crankcase and manifold, then this implies that the oil seals are worn and are in need of replacement.

Why is my oil milky/black?

If your CAT pump has run for a considerable period after the low-pressure and high-pressure seals have worn, water may leak past them and travel along the plunger rod and attach the crankcase oil seals. Water contamination to the crankcase oil can result in this milky consistency, and once has been left to cause a problem, can contain black sludge. If this is the case, the oil will need changing and the drive end components including the bearings and plunger/piston rod of the pump will need inspecting for damage. For that reason, crankcase oils seals should be inspected each the low and high pressure seals are serviced.

2. CAT Pump Seals

Maintenance intervals for CAT pump seals typically range between 1,500 and 8,000 hours, depending of course upon the operating conditions the pump is under. Wear can occur more quickly however if the seals have been subject to excessive temperature, cavitation, dry running, abrasives, harsh water or chemicals.

If you experience any water leaks between the manifold and the crankcase or loss of performance including pressure loss, it is important to check your CAT pump seals immediately. Maintenance of CAT pump low and high pressure seals is vital to prevent damage to other parts of the pump as described previously.

The standard CAT Pump seal kits cover the low and high-pressure seals and their associated O-rings.

3. CAT Pump Valves

CAT pump valves are recommended to be replaced every other seal change. Operating conditions depending, this is typically every 3,000 and 16,000 hours, although like with the seals, temperature, cavitation, dry running, abrasives, harsh water or chemicals can all accelerate wear.

Replacement CAT Pump valve kits are available and include the retainer, spring, valve, seat and necessary O-rings to complete the maintenance.

Other CAT Pump Spare Parts

Whilst the most commonly replaced CAT pump parts are the seals and valves, sometimes the other components require maintenance. This is usually through operating error such as running the pump dry or continued use with worn seals that cause damage to the other parts of the pump:

- Plungers & pistons

- Crankcases

- Gaskets & O-rings

- Shafts

- Bearings

- Barrier slingers

- Manifolds

- Rods

Helping you get “9 lives” out of your CAT pump...

Our 10 year relationship with CAT pumps means that you can expect the most competitive prices on all genuine parts. With many CAT Pump parts available from the factory within 2-3 days of ordering, your maintenance can be carried out quickly.

If you’re in need of CAT pump spares or even a replacement model, then as an experienced CAT pump supplier we can help. To allow us to quote you as quickly as possible, please provide the model number that you will find on the pump label like one of the below.

If your CAT pump model number label is no longer legible, then you will need to follow these instructions:

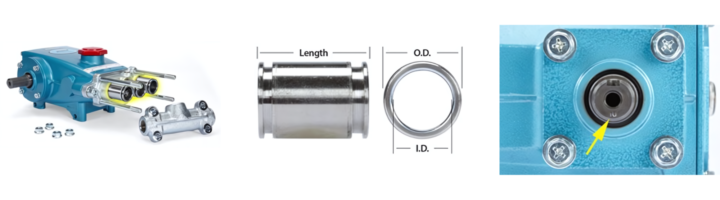

CAT Piston Pump

- Remove pump discharge manifold to access cylinders.

- Measure the inner diameter, outer diameter and length of the cylinder as shown below:

- Identify the stroke of the crankshaft. The stroke is printed on the end of the crankshaft.

- To identify your model number using the piston pump reference chart, click here.

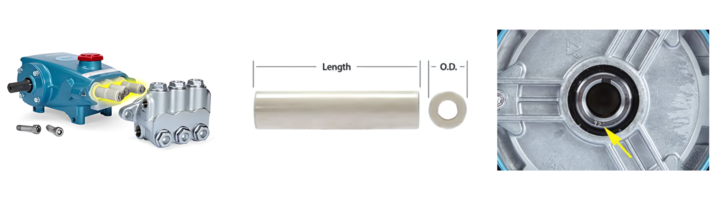

CAT Plunger Pump

- Remove pump manifold to access plungers.

- Measure the length and width of the plunger as shown below.

- Identify the stroke printed on the end of the crankshaft. If you have a hollow shaft pump, you will need to remove the pump from the engine/motor.

- To identify your model number using the plunger pump reference chart, click here.

Looking for CAT pump parts?

With over 15 years of direct partnership with CAT pumps, we can offer the most competitive price on all genuine parts. Supply us with the model and serial number and we will do the rest!