Abrasive Solid Handling Pumps

Abrasive fluids are typically categorised as those that can cause wear and erosion to other surfaces when in forced contact due to the presence of solids. The pumping of fluids containing solids is not a rare requirement, with many different industries carrying out such a process. However, the nature of solid content can massively differ from highly abrasive stones and sharp metal shards, to clogging solids such as rags, tissue and fruit juice pulp, right down to soft, malleable solids often found in food processing.

As you would probably expect, the harder the solid, the larger the particle and the amount of them all impact how abrasive the fluid is. When sourcing or specifying a pump for such an application, these are important factors to determine. However, viscosity also plays an interesting part. Thicker fluids such as sludges can cushion the presence of solids which can reduce their level of abrasion, meaning solids in water-based fluids can be the worst culprits. Just take sand for example. The presence of sand in oil is much less abrasive than if it was in water such as in seawater dredging applications.

When it comes to solids transfer pumps there isn't a one size fits all, so this article will talk through the different types of abrasion resistant pumps and their applications, and how this impacts the pump that is chosen.

Typical high solids pump applications:

- Sewage and effluent transfer

- Biomass e.g. manure, food waste and vegetation

- Waste process water including residue, metal shards

- Waste oils and used cooking oil

- Food processing e.g. fruit pulp, olive oil stones, chopped tomatoes

- Dewatering and rainwater removal

- Bilge water pumping

- Seawater dredging

- Paper pulp slurries

What pump types are usually abrasion resistant pumps?

There are certain pumping technologies that are not suitable for handling even the smallest of particles. Due to their tight tolerances between the casing and the moving parts, vane, gear and side channel pumps will jam when attempting to pass solids and immediate wear will be caused. Magnetic drive pumps are also generally not suitable as abrasive liquid pumps due to the narrow tolerances between the magnets and casing, and if the particles themselves are magnetic, they can cling to the magnetic coupling and cause it to weaken.

Peristaltic pumps, diaphragm pumps and progressive cavity pumps are popular types of abrasive fluid pump. The continuous cavities that exist between the rotor and stator of the progressive cavity design and the slight flexibility of the stator means that even large solids and thick liquids can be handled with ease and without damage. However, the complexity of the design means that maintaining progressive cavity pumps can be more expensive due to the increased wearing parts. At the other end of the spectrum are Peristaltic pumps. These have no moving parts that come into contact with the fluid, meaning they have no valves, seals or impellers to clog or erode. As a result, their solid handling capabilities are just limited to the size of the internal hose and there are less components to maintain, making them another ideal choice for abrasive, viscous fluids with clogging solids such as tissues.

Air operated diaphragm pumps are also an excellent choice as they can pass solids almost up to the size of their inlet/outlet. AODDs a popular solution for abrasive applications in processing plants and factories, as air supply is usually readily available. For small solids, in less heavy duty applications, flexible impeller pumps are another option, thanks to their supple, rubber impellers being able to bend around the particles present in the fluid.

Peristaltic pumps, diaphragm pumps and progressive cavity pumps are popular types of abrasive fluid pump. The continuous cavities that exist between the rotor and stator of the progressive cavity design and the slight flexibility of the stator means that even large solids and thick liquids can be handled with ease and without damage. However, the complexity of the design means that maintaining progressive cavity pumps can be more expensive due to the increased wearing parts. At the other end of the spectrum are Peristaltic pumps. These have no moving parts that come into contact with the fluid, meaning they have no valves, seals or impellers to clog or erode. As a result, their solid handling capabilities are just limited to the size of the internal hose and there are less components to maintain, making them another ideal choice for abrasive, viscous fluids with clogging solids such as tissues.

Air operated diaphragm pumps are also an excellent choice as they can pass solids almost up to the size of their inlet/outlet. AODDs a popular solution for abrasive applications in processing plants and factories, as air supply is usually readily available. For small solids, in less heavy duty applications, flexible impeller pumps are another option, thanks to their supple, rubber impellers being able to bend around the particles present in the fluid.

For applications such as dewatering and flood water pumping that commonly includes abrasive solids such as gravel, submersible pumps are often selected. This is due to the fact that can be immersed into the water for easy installation and easily removed without the requirement of pipework.

Can centrifugal pumps be used for solid handling?

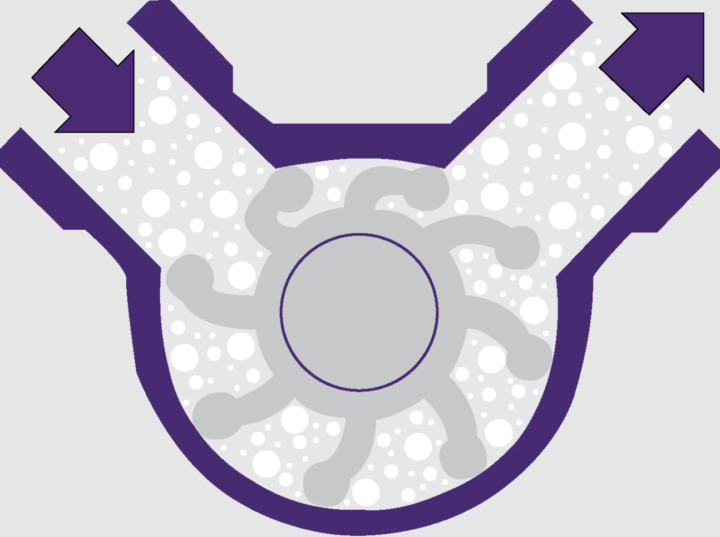

Generally speaking, centrifugal pumps are associated with the handling of clean fluids due to the damage the presence of solids can cause the pump. However, they can in some situations be used as a solid transfer pump provided that that the right impeller is selected. Whilst closed impellers are prone to clogging when in contact with solids, open impellers can handle small particles. Vortex impellers however enable a centrifugal pump to transfer solids without damage but creating a whirlpool/vacuum, which keeps any solids away from the impeller as the fluid is pulled through. Read more about impeller selection here.

The centrifugal design however is most efficient when used with lower viscosity fluids, meaning that whilst it may work for pumping contaminated water or water based solutions, other pump types are preferable for transferring a viscous solid laden slurry such as organic waste.

Does pump size matter when it comes to abrasive solids?

As discussed above, some abrasive fluid pump types such as peristaltic pumps and diaphragm pumps are able to handle solids up to the size of their inlet/outlet. For that reason, sometimes a larger pump than is needed duty wise is often specified for handling a specific solid size, but run at a lower speed. Likewise, at higher speeds and greater differential pressure, wear from abrasive particles can be considerably higher. Therefore, whilst the initial outlay may be more expensive, by running an oversized pump at a lower rpm, it is also likely to help reduce maintenance costs over a solid handling pump's lifespan.

Do you need a low shear pump?

Another factor to consider when selecting a solids transfer pump is whether it is important that the particles remain intact throughout the handling process, which is often the case in the food processing industry. For example, if you are pumping a yoghurt that has fruit pieces inside, you want those fruit pieces to pass through the pump whole. Certain pump technologies such as centrifugal pumps apply high shear due to their close tolerances, meaning that those fruit pieces will end crushed and turned into slurry. Shear sensitive pumps on the other hand such as diaphragm pumps, peristaltic pumps or flexible impeller pumps, a pump design which have supple rubber vanes that move the fluid along, can handle solids without changing their structure due to their low internal velocity.

Some fluids it would not make a difference whether they were kept intact or not. However, at the other end of the spectrum is waste matter such as sewage, where it may actually be beneficial for the pump to crush and chop up the solid content to make it easier to deal with further down the line. In these instances, abrasion resistant pumps can be supplied with grinder or cutter impellers, that chop up the solid as it passes through the pump into smaller, more manageable pieces.

Summary

Whilst this article, discusses how to select an abrasive solids transfer pump, it is important to note that if the fluid is an otherwise, non-difficult fluid to transfer such as water or light fuels, it may be more cost effective to fit a strainer/filter on the suction side to remove the particles, rather than go to the expense of purchasing a pump that can efficiently handle solids. However, if the solid content is very high, the fluid is viscous, shear sensitive or installation doesn't allow a strainer, then an abrasion resistant pump will definitely be required.

When specifying a solid handling pump there is a lot more that goes into it other than the solid handling capabilities itself, such as flow rate, pressure, suction capabilities, compatible materials, installation requirements and even budget. However, here is a summary of the different pump types' performance when it comes to different abrasive fluids:

| Peristaltic | Progressive Cavity | Diaphragm | Flexible Impeller | Centrifugal | |

| Solid Handling | High | Highest | High | High | Impeller Depending |

| Viscosity | High | Highest | High | Medium | Low |

| Non-lubricating, Thin Fluids | Yes | No, can slip | Yes | Yes | Yes |

| Shear | Low | Low | Low | Low | High |

Need a pump for an abrasive fluid?

If you require an abrasive solid handling pump for one of the industries mentioned in our article, then take a look at our range of pumps suitable for abrasive fluids.