7 Ways to Improve the Energy Efficiency of Your Pump

With concerns for the environment growing as well as the ever increasing need to reduce costs, energy efficiency is an important topic for industry. It’s been reported that pumping systems account for nearly 20% of the worlds electrical energy demand, and the US Department of Energy research found that 16% of a typical industrial facility’s electricity costs are generated by its pumping systems. Just this alone shows how important improving the energy efficiency of your pumping systems is…

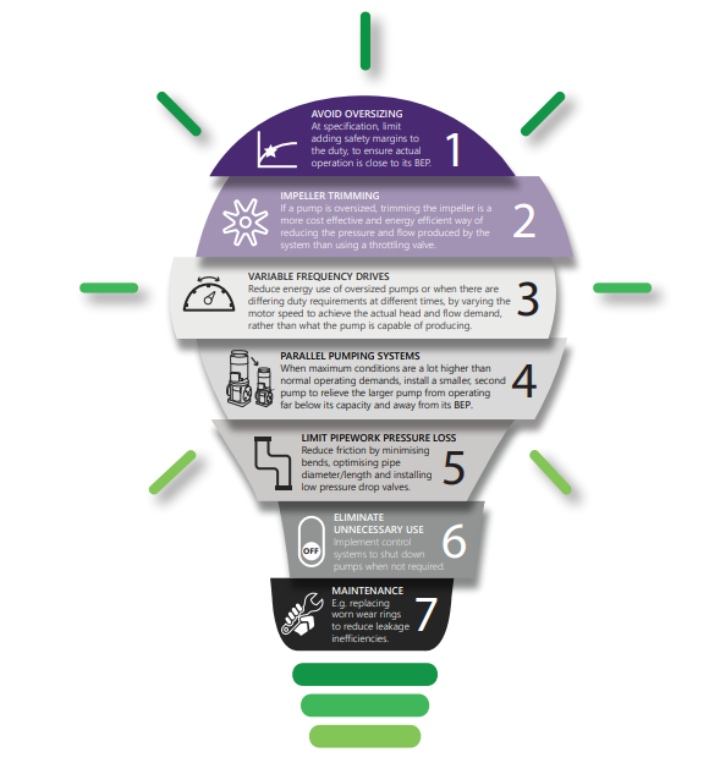

This article covers 7 ways that you can make energy savings on your pumping systems. If you’d rather a quick summary, click to download our handy infographic!

1. Avoid oversizing the pump

It’s common for engineers to be conservative when specifying a pump, with them often including a margin of safety in terms of the supplied pump’s duty compared to what the application requires. It’s well documented that rotodynamic pumps such as centrifugal pumps, which amount to around 80% of all installed pumps, are typically oversized by 20-30%. As a higher performance in terms of flow and pressure requires more power from the motor, an oversized pump can result in unnecessary energy consumption.

Whilst a degree of oversizing may be good common sense to compensate for uncertainties in the design process, selecting a pump that will be operating as close to its Best Efficiency Point as possible can significantly reduce energy usage.

2. Impeller trimming

If a pump is oversized, trimming the impeller is a relatively cost-effective way of reducing the pressure and flow that is produced. Whilst trimming the impeller is much more energy efficient than using a throttling valve to achieve the required duty, as an impeller is shaved, the clearances between it and the casing get larger, making it less efficient than a full-sized impeller. For that reason, variable speed drives are often the preferred choice when it comes to energy efficiency.

3. Variable frequency drives

As their name suggests, variable frequency drives vary the rotational speed of the motor to achieve the actual head and flow demand of the application, rather than what the pump can produce. VFDs are typically used to limit unnecessary energy consumption in two scenarios; the first being to slow the motor down on a pump that has been oversized at specification stage.

The second use of a VFD is where there are differing duty demands on the pump at different times. When this is the case, the pump needs to be able to run at maximum capacity when required but may operate at less than this for long periods of time. A typical example of this is a cooling pump, where the temperature of the equipment/fluid needing to be cooled may vary considerably.

Although VSDs do come at a cost, usually the energy cost saving they can make justify the investment.

4. Parallel pumping systems

The use of multiple pumps is an alternative energy efficient solution to VFDs for a system with different duty requirements. When the requirements of the “worst-case” conditions are significantly higher than normal operating conditions, a single pump could spend most of its working life operating far away from its Best Efficiency Point. The installation of a second, smaller pump that is specified to meet the average system demand would relieve the larger pump from the burden of operating far below its optimum capacity.

5. Limit pipework pressure loss

Optimising the system pipework to limit the frictional pressure drop is another way to save energy, as it reduces the power the pump requires to overcome such losses. Pipe diameter, length, layout internal surface and components installed within the pipework all affect system pressure drop and therefore consideration should be given to these when looking at energy improvements.

At the design stage, attempts should be made to minimise the number of bends, expansions and contractions in the pipework, keeping the piping as straight as possible and the diameter the same. However, due to space constraints this is not always possible. Any fittings or valves specified for the installation should also have a relatively low pressure drop.

In addition, the diameter of the pipework should be carefully selected as smaller diameters will result in more friction. Pipework can be expensive, especially if the fluid being pumped requires more costly materials such as stainless steel, and therefore there is often temptation for the pipework diameter to be made smaller. Corrosion and rust can increase resistance reducing in pressure loss, which means cleaning and maintenance of pipework is important too.

6. Eliminate unnecessary use

Whilst this seems obvious, it’s surprising how often pumps are in operation unnecessarily. Control systems can be implemented to shut down pumps not in use e.g. standby pumps, and the use of pressure switches can control the number of pumps in service when duty requirements vary. This can ensure that multiple pumps aren’t in use at the same time, when the current system conditions only need one pump in action.

7. Carry out maintenance

Undertaking routine maintenance on your pump can also reduce energy consumption, as like with any equipment, wear can reduce efficiency. Pump upkeep including the replacement of eroded wear rings is vital, as increased wear ring clearance increases leakage and therefore the pump power requirements to produce the same flow is increased. A pump’s energy efficiency can degrade as much as 10-25% before it’s replaced. When it gets to this stage, the best way to reduce your pump’s long-term energy costs is to upgrade it!

Could a new pump save you from wasted energy costs?

To find out how you can you can make your pump process more energy efficient, discuss your existing application with our pump experts today.