Water Treatment Industry Pumps

The term “wastewater” is a broad one, but then so is our wastewater pump offering.

The term “wastewater” is a broad one, but then so is our wastewater pump offering.

Are you treating municipal wastewater from domestic/household use or run off rainwater? Or is it industrial process wastewater that may contain chemicals, oil and swarf that is being handled? Having dealt with regional water companies, petrochemical plants, mines and quarries as well as paper, metal and manufacturing sites, we understand the challenges of all.

Whether it’s for the transferring of the wastewater itself, the removal of sludge from a settlement tank, chemical dosing for the treatment process or for pipework flushing, we have a wastewater pump for your requirements.

Where Our Water Treatment Pumps Are Used

Wastewater treatment pumps are used at different stages of the process.

- Clarifier sludge – Clarifiers including lamella plate separators remove suspended solids through gravity settling or sedimentation. The concentrated impurities collected at the bottom of the settlement tank create a sludge that needs to be discharged via a wastewater sludge pump. Due to their ability to handle viscous and solid laden fluids, we typically offer peristaltic, progressive cavity or diaphragm pumps for this.

- Chemical dosing – In the earlier stages, our water treatment dosing pumps can be used for accurately metering coagulants (to group solids dispersed in the water together) and flocculants (to make the grouped solids sink), such as aluminium sulfate and ferric chloride. In latter stages, our chemical dosing pumps are used for lime and sodium hypochlorite for disinfection, softening and adjusting pH levels.

- Pipework flushing – Water treatment plant pumps also include models for the flushing out of pipework to clean it after chemicals have been passed through.

Benefits of Our Wastewater Pump Range

Whether it’s for the pumping of the wastewater itself or for a water treatment pump, cur range covers all applications:

- Capabilities to handle solids up to 100mm, sharp and stringy matter, without damage to the pump internals

- Valve and seal-less options to eliminate the risk of clogging with the presence of solids

- Self-priming and excellent suction capabilities for the emptying of wastewater tanks

- Models available with excellent dry running capabilities to cope with low fluid level

- Water treatment dosing pumps for highly accurate metering of chemicals even at the lowest of flow rates

- Low shear models to maintain the structure of dosed coagulants and flocculants that are sensitive to force

- High pressure capabilities of up to 190M and flow rates up to 6000m3h

- Variable speed drive available to handle differing performance requirements of the water treatment plant pumps

Who We've Worked With

Case Studies

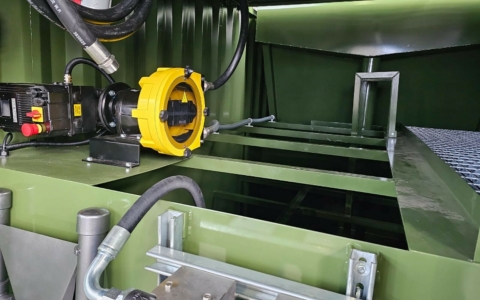

Lamella Settlement Tank Emptying - Peristaltic Pump

We received an enquiry from Northern Tanks, a fabricator of fluid storage tanks and transfer systems. They were in the process of a designing a steel container which would enclose a water tank with pressure washers connected, used to wash down site equipment. Once used, the collected water would be passed through a Lamella Separator and Filter to remove any large solid particles and returned to the original water tank to use again.

Water Treatment Dosing – Peristaltic Pump

Castle Pumps received an enquiry from a company who deal with the collection and treatment of domestic sewage systems and industrial waste. They were looking for a water treatment dosing pump for metering 5-10 litres of ferrous sulphate and caustic soda at a time. Ferrous Sulphate is commonly used as a coagulant in water treatment to bind particles in wastewater together to make them easier to remove, and then caustic soda raises the pH levels after the coagulants lower it.

Ash Laden Waste Water for Power Plant - Vertical Immersion Pumps

Castle Pumps' specialist knowledge means that they often need to advise customers on what type of pump they need. For example, in this case study, the customer thought that they required a submersible pump, however due to the temperature of the fluid being pumped, Castle Pumps recognised that a vertical immersion pump was a better solution.