Pharmaceutical & Cosmetics Industry Pumps

Pumping solutions to limit waste and deliver a pure final product

Pumping solutions to limit waste and deliver a pure final product

If you’re in the cosmetics or pharmaceutical industry, you will have great appreciation for the challenges it poses. When specifying the right pump, there are so many factors to consider such as maintaining the purity of the final product, dealing with the sensitive and expensive fluids being handle and the high accuracy often required for dosing ingredients.

Whether the cosmetic or pharmaceutical pump is for metering a precise batch of active ingredient into a solution, mixing all ingredients of a cream or lotion together, powder coating tablets or transferring medicines to the machine that fills the bottles, Castle Pumps have the solution.

Where Our Pharmaceutical Pumps Are Used

With thousands of different chemicals, fluids and solutions being used throughout almost every cosmetic and pharmaceutical manufacturing plant, there are unlimited requirements for our wide range of pharmaceutical process pumps. Whilst almost all need to be hygienic pumps as they are for human consumption, other factors mean the applications can differ widely:

Common applications we solve include:

- Dosing of active ingredients

- Flavourings, colourings and additives

- Gels, lotions and creams

- Perfumes, alcohols and varnishes

- Soaps and shampoos

- Liquid medicines and syrups

Benefits of Our Pumps for the Pharmaceutical Industry

So, what makes our pumps for the pharmaceutical industry ideal for use in their applications:

- FDA, 3A and EHEDG approved hygienic pumps for the safe and non-contaminating handling of products for human consumption

- Low shear pumps to prevent sensitive products e.g. creams or gels being damaged or altered in terms of texture or taste.

- Metering pumps for highly accurate dosing of chemicals even at the lowest of flow rates

- Clean in Place models for easy stripping and cleaning without removing from installation

- Variable speed drive to slow motor and control flow to meet different requirements

- Preset batch filling to limit operator intervention and improve productivity

- Models with 99.98% emptying capabilities to prevent waste of expensive product at the bottom of the container

- Magnetic drive pumps coupled without mechanical seal to limit leaking hazardous fluid

- ATEX approved for handling flammable chemicals, alcohols, perfumes and varnishes

Case Studies

Vape Flavour Dispensing from IBCs - Food Grade Barrel Pump

Castle Pumps received an enquiry from a manufacturer of vape liquids and flavours who were looking to upscale their production. Part of this involved improving the efficiency of transferring the concentrated flavours from the IBCs where they are stored. The customer was looking for a number of container emptying solutions for fitting onto the IBCs and dispensing the favours without manually handling the fluid. They were looking for a number of container emptying solutions for fitting onto IBCs.

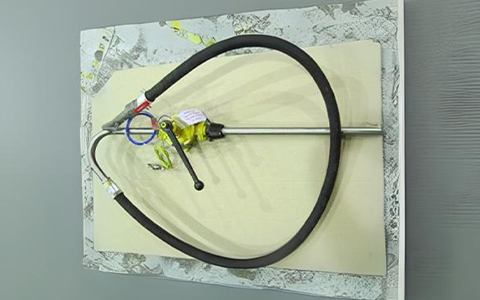

Wax Dosing for Home Fragrance Manufacturer - Peristaltic Hose Pump

One of the UK's largest home fragrance manufacturers enquired about a pump for transferring wax at 60°C, which could do a number of batches within a set time frame. Due to prior experience, we knew which pump would be the best solution for their specific requirements and were able to supply an industrial peristaltic pump, that was low maintenance and relatively low cost.

Acetone Transfer for Royal Veterinary College - ATEX Hand Pump

The Royal Veterinary College contacted us with a unique enquiry. They needed an ATEX rated hand pump for transferring -20°C acetone, which would be used to freeze animal carcasses in their laboratory. The college sent photos of the drum along with the dimensions, to ensure the tubeset was cut to the correct length. We supplied them with their required pump, as well as a discharge hose and nozzle so the customer had easier operation.

Popular Products

- Max Flow Rate: 240lpm

- Max Head: 13M

- Max Temperature: 100°C

- Max Viscosity: 1000 cP

- Solids: 5mm

- Size: 1 1/4"

- Max Flow Rate: 340lpm

- Max Head: 80M

- Max Temperature: 95ºC

- Max Viscosity: 15000 cP

- Solids: 15mm

- Size: 2"

- Max Flow Rate: 1.4lpm

- Max Head: 20M

- Max Temperature: 80ºC

- Max Viscosity: 8000 cP

- Solids: 8mm

- Max Flow Rate: 86lpm

- Max Head: 27M

- Max Temperature: 100°C

- Max Viscosity: 50,000 cP

- Solids: 5mm

- Size: 1'' to 1 1/2"