Oil & Energy Industry Pumps

Solutions for all corners of the ever-evolving energy industry

Solutions for all corners of the ever-evolving energy industry

When it comes to the production of oil, gas or indeed any source of energy, the industry is faced with a number of challenges that make getting the right pump extremely important. Continuous duty requirements, high pressures, harsh and often hazardous installation environments and the handling of abrasive or difficult to pump products, are not uncommon issues.

Specifying solutions for the oil industry has been a key focus of Castle Pumps for at least 15 years. However, in more recent years we have seen the energy industry evolve, with a shift in demand from companies involved in energy from waste and other renewable sources.

Where Our Pumps Are Used in The Oil & Energy Industry

- Oil production – Both upstream and downstream activities rely on our pumps. From the cooling of rig equipment to the transfer of oil based sludges in the drilling process to loading/unloading tankers and cargo ships for transportation and storage.

- Power generation – On one side are the high pressure gear pumps used to feed large diesel generators, typically where the fuel needs to be pumped from a basement to a generator on top of a building. Whereas power plants require cooling pumps and boiler feed pumps for which we typically supply centrifugal and side channel pumps.

- Energy from waste – You will find various pumps in an Anaerobic digestion or biogas production plant, from transferring the high-solid biomass slurries into the digester to pumping liquid into a dry mixture to make it pumpable. Due to the abrasive nature of the fluids, the viscosity of the slurries, and the high chance of solids we typically supply progressive cavity and peristaltic pumps.

Benefits of Our Pumps for The Oil & Energy Industry

- Type approved pumps with class certification by Lloyds, ABS and Bureau Veritas for offshore rig use

- Slurry pumps able to handle solids up to 100mm, highly viscous and abrasive matter, without clogging or damage to the pump internals

- Highly efficient screw and gear pumps capable of handling lubricating fuels and oils without loss of efficiency

- Flow capabilities up to 6000m³h and pressure up to 900m for a large range of duties

- Optional air ejectors and electric priming pumps for applications where a short priming time is required, or where it is not possible to keep the suction flooded

- Back pull out designs to allow the motor to be removed without disconnecting the pump from the pipework during maintenance

- Magnetic drive pumps coupled without the presence of mechanical seals to limit the chance of leaking hazardous or flammable fluid

- ATEX approved models for the safe handling of petroleum based fluids in a potentially explosive environment

Who We've Worked With

Case Studies

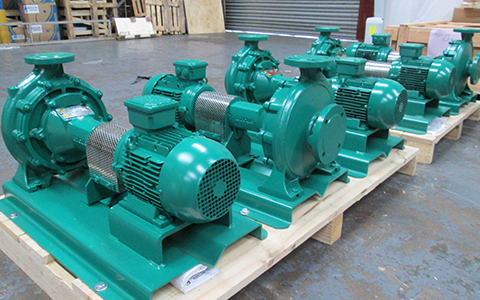

Seawater Cooling of Subsea Oil Rig Winch - Long Coupled Centrifugal Pumps

Here at Castle Pumps we understand that timing is important within the marine and offshore market. Quite often we receive enquiries that need to be dealt with quickly in order for the purchase and delivery to follow suit and minimise lead time. This subsea oil and gas company needed five sea water cooling pumps on a quick lead time. For this customer, we provided five long coupled centrifugal pumps in less than five weeks.

Diesel Generator Feed – Gear Pumps

Castle Pumps received an enquiry from a client who specialise in the design, fabrication and installation of fuel systems and their pipework. They were working on a project for which they were fabricating two duplex pump sets that would be feeding rooftop generators from a bulk diesel tank. Duplex pump systems can be for duty assist, where two pumps contribute to the total output, or duty standby, where one pump acts as a back up in the event of a failure with the first.

Diesel Tank to Tank Transfer for Generator Supplier - Flexible Impeller Pump

When a customer enquires about a pumping system, there is usually a list of specifications that need to be met. Thanks to our team's knowledge and experience, Castle Pumps were able to fulfill our customer's exact requirements. We designed, built and supplied a ready to use system, which cut the customers extraction process time to under two hours.