Mining & Quarry Industry Pumps

Pump solutions for environments where other pumps fail!

Pump solutions for environments where other pumps fail!

The nature of the industry means that pumps for mining and quarries are usually running under heavy operating conditions, pumping corrosive or abrasive liquids or in harsh environmental conditions such as dusty or explosive ones. This alone shows the importance of having confidence that you’re getting the right pump that can perform reliably under such settings.

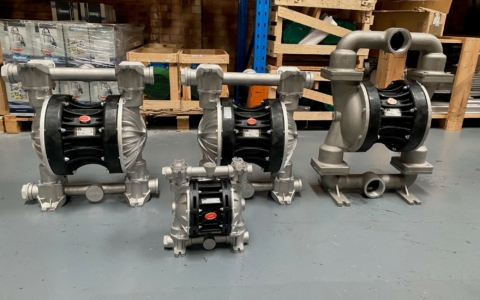

Castle Pumps have over 15 years’ experience dealing in the mining, quarry, blasting and drilling industries, supplying them with trusted brands of mining slurry pumps, dewatering pumps and lubricant pumps.

Where Our Pumps For Mining Are Used

There are a wide range of processes within the mining, quarry and site environments for which heavy duty pumps are required. From wastewater to slurries to chemicals to lubricants, Castle Pumps have experience in supplying pumps for all.

Common applications we solve include:

- Drainage and dewatering

- Contaminated wastewater

- Highly abrasive slurries

- Lubricant transfer for machinery

- Chemical pumps for leaching

- Water treatment & pH adjustment

- Washing down of aggregates or minerals

- Raw water supply

Benefits of Our Pumps for The Mining Industry

Whether it’s for the pumping of the wastewater, handling slurries or chemicals for treatment, cur range covers all applications:

- Mining slurry pumps able to handle solids up to 100mm, sharp and abrasive matter, without damage to the pump internals

- Valve and seal-less options to eliminate the risk of clogging with the presence of solids

- Self-priming and excellent suction capabilities along with excellent dry running capabilities to cope with low fluid level in pits

- Chemical metering pumps for highly accurate dosing of chemicals even at the lowest of flow rates

- Control features to help productivity such as variable speed, dry run protection, level switches and batch meters.

- Magnetic drive pumps coupled without the presence of mechanical seals to limit the chance of leaking hazardous fluid

- ATEX approved models for the safe handling of flammable chemicals or fluids in a potentially explosive environment

Who We've Worked With

Case Studies

Heavy Grout Transfer for Drilling Specialist - Peristaltic Pump

This customer needed to replace their current pump as it was not completely suitable for their application - lacking control features which meant supervision was required when start/stopping the pump. We provided them with a completely bespoke peristaltic pump specifically designed for their application. It had all the desired control features, allowing supervision-free operation and improving their productivity. One of the main problems they had was having to operate the pump manually.

Castor Oil For Resin Bound Aggregates – AODD Pumps

Castle Pumps received an enquiry from an aggregates company who produce a wide range of aggregates for landscaping, road surfacing and construction. They had already purchased some AODD pumps from us for one of their sites, and after being impressed with their performance were now back with an enquiry for similar pumps for a different site. They were building a new process for pumping castor oil.

Water Based Dye Transfer – Peristaltic Pumps

Castle Pumps have been working for a good few years now with a manufacturer of site machinery for the quarry, mining, aggregate and forestry industries. They originally approached us when they were in need of a pump to be used with one of their large-scale colouring trommels. The trommel works by moving mulch, wood chippings, aggregates and sand in large volumes along a conveyor whilst spraying it with dye to colour it for landscaping.