Marine Industry Pumps

Pumping solutions trusted in over 22,000 vessel builds worldwide

Pumping solutions trusted in over 22,000 vessel builds worldwide

When it comes to onboard pumps, reliability is not a factor that can be questioned. That’s why Castle Pumps are proud to be the UK agent of Azcue Pumps; a manufacturer of marine type approved pumps for over 100 years, with some of the largest names in ship building trusting their quality.

With 15 years’ experience specifying new marine pumps and replacing existing models onboard, Castle Pumps have built a large network of customers spanning ship builders, vessel repairers, marine resellers, ship owners and management companies.

Where Our Marine Pumps Are Used

Unlike many marine pump suppliers, we don’t just supply pumps for seawater! We are a single source of supply of marine class certified pumps to passenger ferries, cargo ships, super yachts, service vessels and offshore rigs for water, fuels, lubricants and slurries. Common applications we solve include:

- Seawater and fresh water cooling

- Ballast tank filling/emptying

- Marine fuel (MGO, HFO, LSFO)

- Lubricant transfer

- Bilge water removal

- Boiler feed

- Desalination/reverse osmosis

- Black and grey water

- Fish waste

Benefits of Our Pumps for The Marine Industry

So what makes our range trusted by the marine and offshore industry:

- Marine type approved pumps with class certification by Lloyds, ABS and Bureau Veritas.

- A complete offering of centrifugal, vertical inline, screw, side channel and immersion pumps for all onboard applications

- Full material offering; cast iron for fresh water and fuel oils, bronze for sea water as standard. Stainless steel available upon request.

- Flow capabilities up to 6000m³h and pressure up to 900m for a huge range of duty requirements

- Optional air ejectors and electric priming pumps for applications where a short priming time is required, or where it is not possible to keep the suction flooded

- Back pull out designs to allow the motor to be removed without disconnecting the pump from the pipework during maintenance

- A guaranteed supply of genuine spare parts for at least 15 years after model discontinuation to ensure entire lifetime servicing

- 100% pump testing regime before dispatch from the factory in Spain

Who We've Worked With

Case Studies

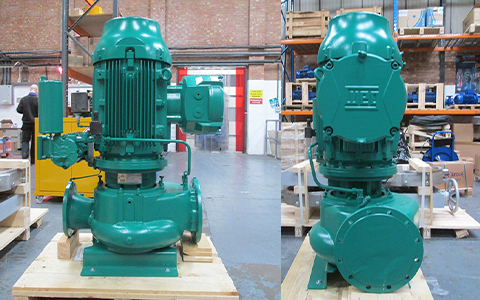

Ballast Water System Upgrade - Vertical Inline Centrifugal Pumps

Castle Pumps received an enquiry from a new customer who needed to upgrade their ballast water system, in order to meet the 'Ballast Water Management Convention 2017' regulation. We supplied Azcue cast bronze pumps to ensure that all wetted parts that come into contact with the seawater are non-ferrous and therefore would not corrode. Ballast water pumps transfer seawater to and from the ballast tanks in order to add weight to the ship for stability, so reliability is key.

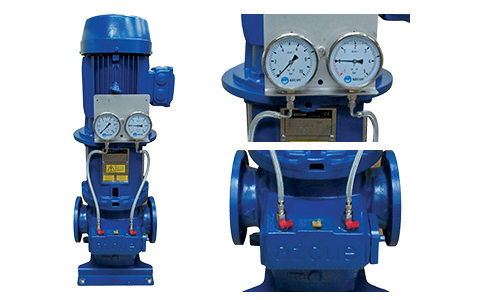

Marine Gas Oil Conversion for Ferry Operator - Screw Pump

A UK ferry operator required a verticle inline screw pump with Lloyds approval, due to undergoing a marine gas oil conversion. The customer needed the pump in 3-4 weeks in order to meet the vessels dry docking program. Castle Pumps supplied a vertical inline screw pump in just over 3 weeks, complete with marine certification. In result of our quick response and supplying the pump within the time needed, we were also asked to supply a DN80 strainer and flowmeter suitable for MGO.

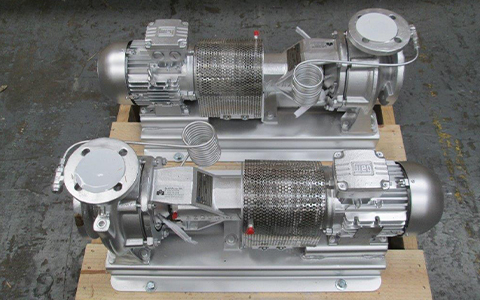

Boiler Feed for World's Largest Container Ship - Type Approved Centrifugal Pumps

Castle Pumps have been specifying and supplying pumps for the marine market for several years, and therefore have expertise and knowledge when it comes to marine enquiries. The world's largest container ship in 2012 contacted Castle with an urgent enquiry, requiring two boiler feed pumps. Castle Pumps were able to select a model that matched their requirements and dispatch them in just 9 working days!