Case Studies

With over 15 years' experience specifying and supplying pumps, we have probably delivered a solution like yours before. Take a look at just some of our past projects.

Seawater Cooling for Refrigeration Engineers - Self Priming Centrifugal Pumps

Castle Pumps' range is so vast that it includes pumps that other distributors do not have access to. For example, in this case study the client had approached other suppliers who were unable to fulfil their requirement of a self priming centrifugal pump able to handle flow rates of up to 8,300 l/min. Castle Pumps however were able to find the customer a solution.

Viscous Resin Transfer for Stamp Manufacturer - Barrel Pump

Castle Pumps have a wide customer base including many manufacturing companies in different industries. As a result, there are very few liquids or pumped medium that we do not have experience in specifying a solution for. In this instance, the customer were struggling to find a pump for photopolymer resin, yet our experience knew that a progressive cavity barrel pump would be ideal.

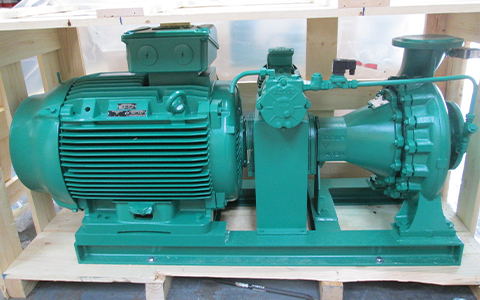

Seawater Cooling of Distillery Heat Exchanger - Long Coupled Centrifugal Pumps

Castle Pumps help customers to solve problems when quoting and specifying equipment. In this case study, the client was experiencing costly downtime due to a worker in the distillery having to keep manually priming the pump when it lost its prime. In order to overcome this issue, Castle Pumps provided two self-priming pumps; one as the main pump and one for standby to completely limit the risk of downtime.

Jet A1 Transfer for Aerospace Test Rig - Side Channel Pump

Castle Pumps are able to source pumping solutions to satisfy even the most stringent of criteria. This case study is an example of where this has been the case. The customer here required an ATEX Zone 1 rated pump that would handle high amount of vapour pressure as well as high suction lift, which combined made a challenging enquiry that we were able to solve.

Ash Laden Waste Water for Power Plant - Vertical Immersion Pumps

Castle Pumps' specialist knowledge means that they often need to advise customers on what type of pump they need. For example, in this case study, the customer thought that they required a submersible pump, however due to the temperature of the fluid being pumped, Castle Pumps recognised that a vertical immersion pump was a better solution.

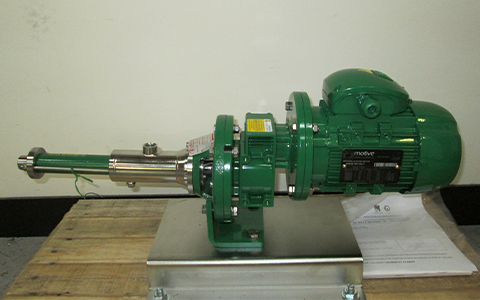

Lubrication Dosing for Decking Manufacturer - Progressive Cavity Pump

Castle Pumps pride themselves on being able to specify and design solutions to meet individual customer needs. This case study demonstrates this, where in order to meet the adjustable flow rate requirements of dripping lubricants onto wood fibres, Castle Pumps ensured that a motor variator was added to the unit to control the speed of the pump.

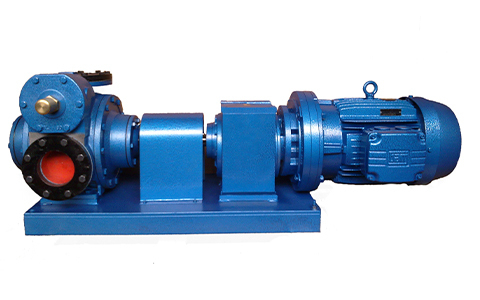

Asphalt Transfer for Fuel Oil Cargo Ship - Screw Pump

Castle Pumps have a lot of experience in the marine industry including specifying and supplying pumps that are to be used on board new ships. Like in this example, where a screw pump was supplied to an asphalt carrier as a cargo booster pump, specifications often change when supplying a new build which makes the project more complex.

Low Temperature Anti-Freeze Circulating for Test Rig - Vane Pump

Castle Pumps pride themselves on the slogan "Whatever the process, we have the pump". In this case study, the client had been informed by other suppliers that they were unable to source a circulating pump that could handle the extremely low temperature of -40ºC. Thanks to the wide range we have access to, we were able to find a pump that did the job and fulfil the customers requirements.

Grease Transfer for Offshore Wind Turbine Installer - Barrel Pump

Castle Pumps' experience supplying to a range of different markets means that they have detailed knowledge on certain industry requirements. For example, in this case study the customer requested a barrel pump for grease. However, due to being used within a marine environment, Castle Pumps knew that the materials needed to be corrosion resistant and therefore a stainless steel tube set was supplied.

Mud Transfer for Oil Drilling Company - Progressive Cavity Pumps

Castle Pumps pride themselves on being as flexible as possible to ensure that they meet the client's requirements. In this example, the customer required a pump with a range of features including ATEX motors, dry run protection and variable speed drives. On top of this, the pump needed to be supplied with counter flanges for immediate installation and supplied within a reasonable time frame; all of which were delivered.

Ballast Water Transfer for Vessel - Vertical Inline Pump

Castle Pumps have built solid relationships with many industrial pump manufacturers, which gives us confidence in our ability to meet tight project time scales. This case study illustrates this, where we were able to get two ballast pumps manufactured and marine certified in three weeks less than the industry standard lead time.