Case Studies

With over 15 years' experience specifying and supplying pumps, we have probably delivered a solution like yours before. Take a look at just some of our past projects.

Water Learning Feature at a School - Diaphragm Hand Pump

A company that specialise in creating natural environments for children through hands on experimental learning, asked Castle Pumps to provide a child friendly but robust hand pump for an outdoor play area. We provided them with a single diaphragm hand pump, a pump that is often used within the marine industry due to it being robust and capable of working in all conditions - perfect for an outdoor installation - resulting in further orders from this company.

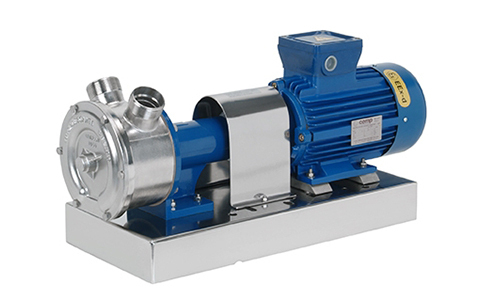

Sea Water Cleaning System for OEM - Centrifugal Pump & Vortex Impeller

Castle Pumps have scores of experience supplying pump solutions to the marine industry. An existing customer contacted us with a new enquiry for a solids handling sea water pump, which needed to be less costly and have better lead times than existing pumps. We offered and supplied a non-clogging centrifugal pump with a vortex impeller, which can handle solids as large as the discharge diameter. Minimal modifications were needed to their existing system and lead time and price were improved greatly.

Fuel Oil Handling for Engineering Company - Long Coupled Centrifugal Pumps

As well as pumps, Castle Pumps can also supply customers with other industrial equipment such as valves. In this example the customer needed some affiliated equipment, as well as pumps. We supplied the customer with centrifugal pumps, peripheral pumps, a re-circulation valve and a duplex strainer. We also consolidated the order into a single shipment, packaged everything for shipment, prepared the necessary documents and shipped to the client's nominated delivery port - hassle free!

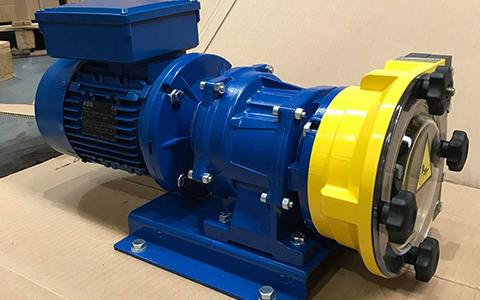

Anaerobic Digestion Plant

One of the services supplied by Castle Pumps, is pump solutions. This customer was having difficulty with its immersible transfer pump and needed a suitable alternative that would eliminate problems caused by blockages, could handle waters and slurries and would optimise installation to improve efficiency. Castle pumps recommended and provided a peristaltic pump, which carried all the features needed in order to solve the issues the client was having prior to the enquiry.

HVAC Water Supply for Deep Sea Vessel - Self Priming Centrifugal Pump Packages

Castle Pumps not only supply individual pumps, but also complete pump packages including ancillary items. The customer needed a portable, self priming, variable speed water supply pump package which could be powered by the clients vessel whilst in a dry dock. By designing, building, testing and supplying the customer with the pump package, it enabled the vessel to be completely autonomous in the supply of fire water, AC and refrigeration services.

Thermal Oil Pumps for a Wood Treatment Facility

Castle Pumps have in house software that is able to select and compare pumps in their database, in order to match the client’s specification. The customer wanted replacement units but wanted to re-use their existing control panels, as well as needing the pump to handle thermal oil operating temperatures of 300ºC. Once confirmation had been given and everything was agreed, a quote was generated within 48 hours.

Aviation Fuel Transfer for Aerospace Test Rig - Long Coupled Side Channel Pumps

Castle Pumps are able to customise pumps for many clients and this is a prime example of taking a pump and modifying it so that it is suitable for conditions natural for that industry. The customer wanted to incorporate pumps which could handle varying temperatures and flow rates within an ATEX Zone 2 environment. Castle Pumps delivered to the brief including both precise instructions and the specified budget within the quotation process.

Seawater Sanitation Onboard a Vessel - Vertical Immersion Pumps

Castle Pumps have a wealth of experience supplying pumps to the marine industry, and we ensure that we match the features of the pump to the specific application at hand. This case study demonstrates this, as we knew that for guaranteed reliability for emptying a sump of sea water and waste solids, a pump with vortex non-clogging impellers would be required and the material would be best in bronze to avoid corrosion from the sea water.

Fresh Water Supply to Diving Chamber - Belt-Driven Plunger Pump

Castle Pumps customise and engineer pumping solutions when required, to ensure that they match the customer's bespoke requirements exactly. In this case study, we put together a ready to use skid mounted pump system complete with pump, motor, belt drive, guard and steel base to meet their requirement for a high pressure, low flow solution.

Transfer of Saline Solution at a University - Peristaltic Pumps

Castle Pumps' experience in the pump market means that the customer is always advised on the ideal type of pump for their application. In this example where a saline solution needed to be transferred slowly, Castle Pumps knew that a peristaltic pump was a perfect fit due to its low flow rate and the fact that the only wetted part that needs to be compatible with the solution was the hose.

Bulk Lube Offloading System for Mining Machinery - Screw & AOD Pumps

Castle Pumps are a "one stop shop" for pumping solutions, priding ourselves on being able to fulfil the customer's complete enquiry. This case study is an example of where we have ensured that the client only requires one point of contact for their pumping requirements. A mining company contacted us with an enquiry for both air operated and electrically driven lube oil pumps, which we were able to specify and supply.

Pond Water Containing Silt for Dewatering Contractor - Self Priming Centrifugal Pumps

Castle Pumps understand that in some situations the customer has very specific requirements including flow rate performance and drive type that the pump needs to be matched to. Here, a dewatering contractor required an engine driven pump to remove 600m³ of water from a pond in 6 hours. We were able to source the ideal solution for this application, ensuring that two pumps with reliable engines were supplied to prevent the likeliness of downtime.