Case Studies

With over 15 years' experience specifying and supplying pumps, we have probably delivered a solution like yours before. Take a look at just some of our past projects.

Sewage Discharge for Leisure Yacht - Progressive Cavity Pumps

An engineering company who were refurbishing a leisure yacht needed pumps for the sewage and oily waste water tanks, but were having trouble sourcing surface mounted self-priming pumps that would fit into the allocated space, that would perform the required duties. Castle Pumps came up with a solution and provided them with a unique range of progressive cavity pumps that matched their requirements and delivered them to the engineers in just over four weeks.

Diesel Transfer System for Generator Manufacturer - Gear Pumps

This generator manufacturer customer needed a pump set for transferring fuel in bulk with a lift height of 26.5 meters and total pipe length of 80 meters. We were able to select 2 of our gear pumps which were ideal for the requirements this customer was after.

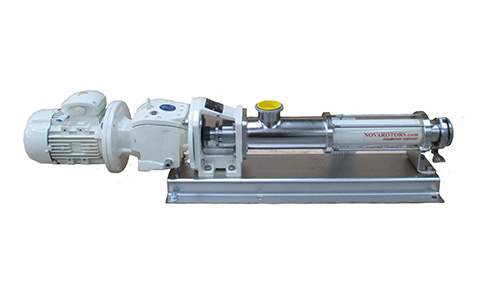

Fuel Transfer for Fuel Filtration/Cleaning OEM - Progressive Cavity Pumps

Our customer, a Fuel Cleaning OEM, was having trouble expanding the capacities of their fuel cleaning systems and required pumps that were not readily available from their previous supplier. They required a close coupled progressive cavity pump with integral relief valves to produce certain flow rates and pressures, and needed it in multiple voltages. Castle Pumps were able to offer the Nova Rotors Wobble Pump Series, which matched all of their requirements.

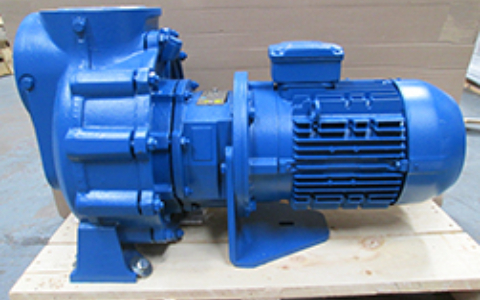

Seawater Dredging Pump for UK Company - Self Priming Centrifugal Pump

This UK based Marine Dredging company required a self-priming centrifugal pump, in cast iron to save costs, for transferring sea water containing small amounts of sand. We selected a horizontal self-priming centrifugal pump with a cast iron casing and bronze impeller from our CA range, capable of allowing 10% passage of sand content in the sea water.

Thermal Furnace Oil Pump for UK Oil Manufacturer - Vane Pump

A UK oil manufacturer wanted a vane pump which could pump furnace oil as well as needing the pump to clear the lines and dry run for short periods of time. The customer had received a quote from elsewhere but the lead time was 6-7. Here at Castle Pumps we were able to supply a vane pump fitted with duravanes, an ATEX motor and a pressure relief valve. We were able to make and deliver the pump, baseplate mounted, within 4 weeks.

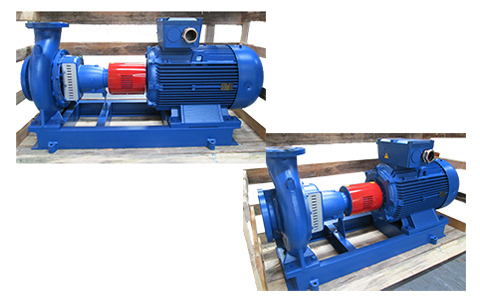

Kerosene Transfer for Offshore Engineering - Long Coupled Centrifugal Pump

An offshore engineering company required a surface mounted pump which could pump kerosene. The customer had some budget restraints which we needed to review. Due to these constraints, we supplied the centrifugal pump in a low cost material, with an explosion proof motor - making it perfect to handle kerosene. The customer was happy with the finished product and it was delivered to them in Nigeria within 10 working weeks.

Onboard Fire Fighting for Subsea Oil & Gas - Vertical Inline Centrifugal Pump

This existing customer needed to upgrade their fire pump system on board their vessel and decided to contact us due to our reliability with past projects we have done for them. Due to the extensive knowledge and experience we have on the marine sector, Castle Pumps were able to meet the customers specific requirements and provide them with an ideal pump which was manufactured and marine certified in fewer than 8 working weeks.

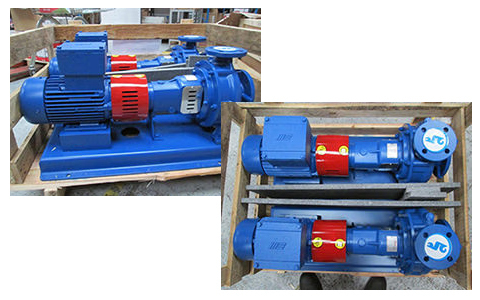

Fuel Transfer for Patrol Boat Fuelling Station - Long Coupled Centrifugal Pumps

This customer needed to purchase various pumps for a fuelling station that they were building off the coast of Malta. The pumps needed were to transfer kerosene, diesel and petrol from storage tanks at the fuelling station, to the boats being refuelled. With this, as well as other factors, Castle Pumps were able to supply centrifugal pumps that matched their requirements and budget, and were delivered within 10 working weeks to the customer.

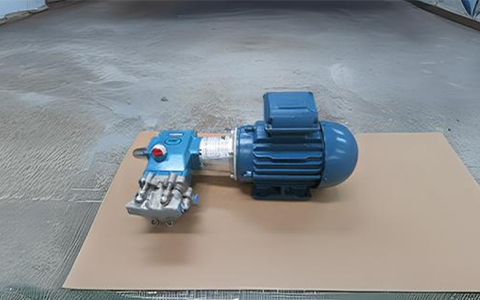

Reverse Osmosis/Desalination for Private Boat - High Pressure Plunger Pump

A private boat owner was installing a reverse osmosis system aboard their vessel and required a high pressure pump for the system to convert sea water into fresh water - at a duty of 8.8 L/min at 35 Bar. Due to our wealth of experience with reverse osmosis systems; we were able to select a plunger pump that matched their requirements.

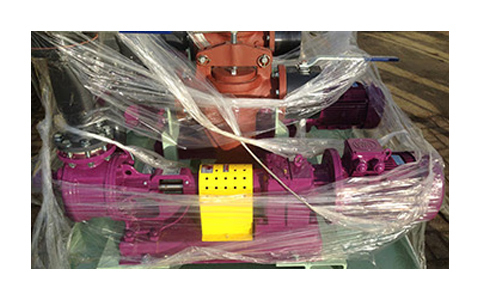

Lube Oil Transfer for Tanker Loading Specialist - Gear Pumps

This customer required a gear pump for their 4 custom skids that they were building. Each pump was required to transfer 30m³/hr at 4 bar and to have a built in bypass. Each pump was coupled to an 11Kw geared motor running at 400RPM to achieve the required duty. We also supplied detailed drawings of the pump, to allow the customer to begin manufacturing the skid before the pumps were delivered.

Olive Oil Transfer Within Production Line - Progressive Cavity Pump

Castle Pumps understand that in situations involving products for human consumption, hygiene is the most important factor to focus on. We chose a progressive cavity pump which is ideal for the pumping of shear sensitive products such as olive oil, as well as it's ability to handle abrasive solids. After carefully selecting the most appropriate materials to modify the pump, it was delivered to our customer within four workings weeks from the initial enquiry.

Bitumen Emulsion for Electrical Engineering Company - Gear Pump

Castle Pumps pride themselves on providing perfect solutions to every customer’s requirements and this case study is a prime example. In addition to a quick turnaround, the customer needed a precise operating temperature, capacity and discharge pressure, and the fluid needed to maintain the same temperature whilst being pumped. Thanks to our extensive knowledge and experience, we provided the customer with a pump that matched their requirements just 32 days from their initial enquiry.