Case Studies

With over 15 years' experience specifying and supplying pumps, we have probably delivered a solution like yours before. Take a look at just some of our past projects.

Vape Flavour Dispensing from IBCs - Food Grade Barrel Pump

Castle Pumps received an enquiry from a manufacturer of vape liquids and flavours who were looking to upscale their production. Part of this involved improving the efficiency of transferring the concentrated flavours from the IBCs where they are stored. The customer was looking for a number of container emptying solutions for fitting onto the IBCs and dispensing the favours without manually handling the fluid. They were looking for a number of container emptying solutions for fitting onto IBCs.

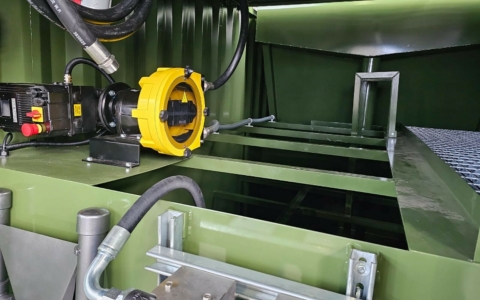

Lamella Settlement Tank Emptying - Peristaltic Pump

We received an enquiry from Northern Tanks, a fabricator of fluid storage tanks and transfer systems. They were in the process of a designing a steel container which would enclose a water tank with pressure washers connected, used to wash down site equipment. Once used, the collected water would be passed through a Lamella Separator and Filter to remove any large solid particles and returned to the original water tank to use again.

Wine Transfer in Winery - Flexible Impeller Pump

We received an enquiry from a contract winemaker based in the UK. They required a food grade pump to transfer wine at temperatures between 2 and 65⁰C, with a maximum flow rate of 15,000 litres per hour and ideally the option of variable speed to enable more control. Due to the nature of their application and the specifications required, we supplied the Liverani All in One Flexible Impeller Pump which was a perfect fit for their requirements.

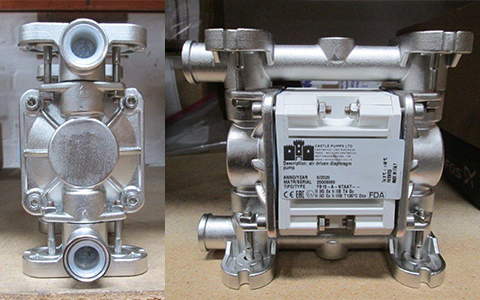

Frozen Food Manufacturer - Air Operated Diaphragm Pump

Castle Pumps received an enquiry from one of the largest frozen food manufacturer brands in the UK that needed a replacement chemical pump for cleaning the processing plant and equipment. Due to the air supply being already available on-side and reliability being key, we specified Debem Boxer 50 AOOD pump. We carefully selected all pump elements to ensure they are compatible with the cleaning chemical and handle the hazardous application.

Transfer of Hot, Viscous Bolognese Sauce - Food Grade Barrel Pump

As well as pumps for industrial and marine applications, Castle Pumps can also supply pumps for the food grade market. This was a new customer that was enquiring about a pump to transfer Spaghetti Bolognese from production to packaging when hot. Castle Pumps visited site to get as much information as possible, and by using our extensive knowledge and past experience we were able to design a bespoke pump kit and supply all within five working weeks.

Heavy Grout Transfer for Drilling Specialist - Peristaltic Pump

This customer needed to replace their current pump as it was not completely suitable for their application - lacking control features which meant supervision was required when start/stopping the pump. We provided them with a completely bespoke peristaltic pump specifically designed for their application. It had all the desired control features, allowing supervision-free operation and improving their productivity. One of the main problems they had was having to operate the pump manually.

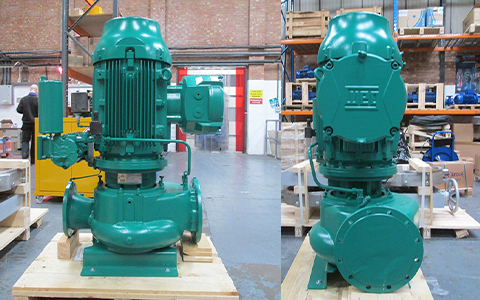

Marine Gas Oil Conversion for Ferry Operator - Screw Pump

A UK ferry operator required a verticle inline screw pump with Lloyds approval, due to undergoing a marine gas oil conversion. The customer needed the pump in 3-4 weeks in order to meet the vessels dry docking program. Castle Pumps supplied a vertical inline screw pump in just over 3 weeks, complete with marine certification. In result of our quick response and supplying the pump within the time needed, we were also asked to supply a DN80 strainer and flowmeter suitable for MGO.

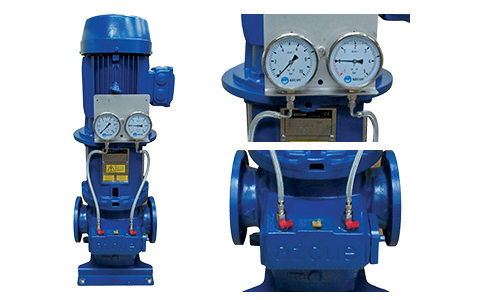

Ballast Water System Upgrade - Vertical Inline Centrifugal Pumps

Castle Pumps received an enquiry from a new customer who needed to upgrade their ballast water system, in order to meet the 'Ballast Water Management Convention 2017' regulation. We supplied Azcue cast bronze pumps to ensure that all wetted parts that come into contact with the seawater are non-ferrous and therefore would not corrode. Ballast water pumps transfer seawater to and from the ballast tanks in order to add weight to the ship for stability, so reliability is key.

Electronic Healthcare Diagnostic Systems Manufacturer - Barrel Pump

We received an enquiry from a new customer who makes electronic diagnostic machines for healthcare professionals. They needed a chemical transfer pump that can handle abrasive and flammable fluids for emptying their cleaning tanks. Using our expertise, we specified a Flux F430 barrel pump with a 1500mm stainless steel shaft and ATEX motor, perfect for abrasive application and fitting into the tank. We also recommended a maintenance kit with spare parts to ensure they had them ready on-site.

Paint & Powder Coating Manufacturer - AODD Pump

We received an enquiry from an industrial paint manufacturer who needed a pump for their oil/solvent mixture. The fluid was being used to clean used containers, before returning to the tank and starting the cycle again. With a cost-saving process and reliability being key, we chose a Debem AODD Pump. They are made with long life diaphragms designed for more than 50 million cycles and have fewer internal wearing parts to maintain.

Food Waste Management - Peristaltic Pump

We received an enquiry from a food waste management company looking to pump a caking mix of bran and water. The viscous nature of this fluid meant that the pump technology chosen needed to be carefully selected to ensure no clogging, damage or running problems. Our experience allowed us to pick a peristaltic pump able to do just this. The pump design has no valves or impellers to clog, making it ideal for thicker fluids containing solids up to 35mm in size..

British Apple Company – Air Operated Diaphragm Pump

Castle Pumps received an enquiry from an apple grower which supplies worldwide cider manufacturers with apple juice from concentrate. They required a pump to transfer small quantities of juice at a time, but was unsure of the fluid's viscosity. Using our experience we were able to determine the viscosity through asking a number of questions, and were therefore able to provide our food grade solution suitable for their needs.