Soup Transfer – Food Grade Progressive Cavity Pump

Case Study Information

- Customer: Stainless Steel Fabricating Company

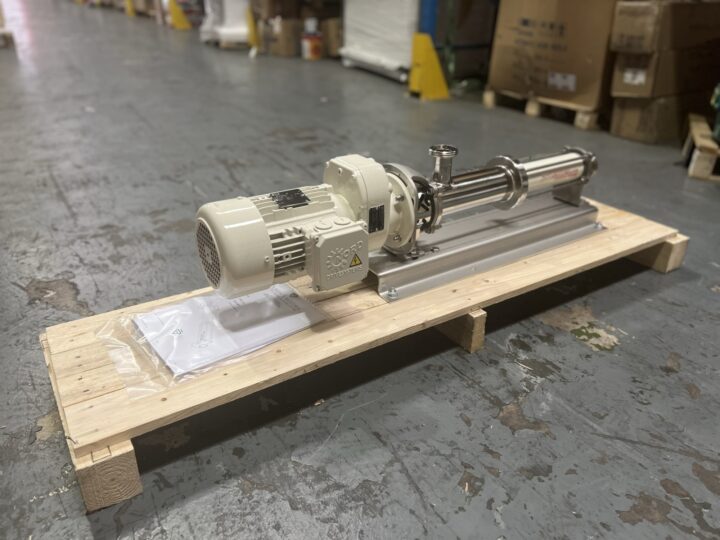

- Pump: Nova Rotors DX-JX Food Grade Progressive Cavity Pump

- Application: Soup Transfer

- Industry: Food & Drink

Enquiry

Castle Pumps received an enquiry from a Stainless Steel fabricating company, who specialise in the design and manufacturer of equipment for the food processing industry. A project they were commissioned to work on required a pump to be installed onto the equipment they were manufacturing, which we were happy to help specify.

The pump was needed to transfer soup, which could contain both meat and vegetable pieces. Due to the pump being used for handling food products, they of course need this to be a food safe pump and able to be cleaned in place to ensure the soup remains safe for human consumption at all times.

Key challenges:

Able to handle the meat and vegetable chunks in the soup without clogging

Shear sensitive fluid – needed to keep the soup intact without crushing the solids

Food grade approvals required

Solution

Equipment Supplied

Model: Nova Rotors DX Food Grade Progressive Cavity Pump

- Max Flow: 6.9m3/h

- Max Pressure: 6 bar

- Fluid: Soup

- Orientation: Horizontal

- Voltage: 230v

- Material: AISI 316 Stainless Steel

- Suction/Discharge: 1"

- Certifications: FDA, 3A and EHEDG

- Drive: Close coupled gear motor

- Mounted: Stainless Steel Base Plate

The requirement for a food grade pump was no problem for Castle Pumps, as we regularly supply solutions to the food and drink industry, What we did want to carefully consider was the gentle handling of the meat and vegetable chunks within the soup. Not only did the selected model need to be able to pump these solids without clogging, but also be able to keep them fully intact so that they weren’t crushed and turned to slurry within the soup.

Given the above point and the duty requirements at hand, we specified a food grade progressive cavity pump. The progressive cavity pump design is known for handling viscous, solid laden fluids whilst applying low shear to the fluid as it is passes through. This fully stainless steel model is also of complete sanitary design, free of dead zones, ideal for clean in place and fully compliant with FDA, EHEDG and 3A.

With production of the soup relying on this pump, reliability for this customer’s application was paramount. Our longstanding relationship with the manufacturer meant that we had full confidence in specifying this solution. Their progressive cavity pumps have a patented pin joint designed for 8000 hours before maintenance is required and consumes 20% less power than other models thanks to its long pitch rotor.

Looking to upscale your food production?

From viscous, solid laden sauces to shear sensitive creams to fruit juices or wine, we can specify the right food processing pump so that you can increase production and reduce costs.