Wax Dosing for Home Fragrance Manufacturer - Peristaltic Hose Pump

Case Study Information

- Industry: Chemical & Process

Customer: Scented Candle/Home Fragrance Manufacturer

Application: High viscosity wax dosing

Equipment Supplied: 1 x peristaltic pump

Location: UK

Equipment supplied

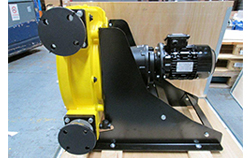

1 x Close Coupled Peristaltic Pump

- Model: FMP-50

- Application: Wax Dosing Pump

- Fluid: Rapeseed Wax

- Temperature: 60 °C

- Viscosity: 20 cP

- Flow: 3000 l/h

- Total head: 15 m

- Design Pressure: 8 Bar

- Hose: NBR (Nitrile)

- Connections: Stainless Steel AISI-316

- Pump Casing: Cast Iron + Polyester Powder Coating

- Gear Box/Reducer

- 1.1 kW, 230/400V, 3 Phase, 50 Hz, 34 rpm, Prot. IP-55

- Suction/Discharge Flange Size: DN-40

Enquiry

We received an enquiry from one of the largest home fragrance manufacturers in the UK who had a requirement for transferring a thick rapeseed wax at 60°C. They were looking for a dosing pump as their production line required the pump to batch transfer 400kg of wax in 10 minutes, and the pump would be running intermittently with a maximum of 3 the batches per hour.

Key challenges:

- Able to handle a viscous, shear sensitive wax

- Capable of accurately dosing batches of the medium

Solution

The first thing we considered when specifying a solution was the fluid. Wax is a viscous and shear sensitive fluid, so we needed a high viscosity pump that would be able to handle the thickness without changing the structure of the medium too much. From experience we knew that peristaltic hose pumps are more than capable of handling the fluid due to their ability to handle viscous products, whilst applying a low shear, gentle pumping action.

Offering a peristaltic pump also fit the fragrance manufacturer's dosing requirement as they are very effective in accurate batch transfer where a fixed flow rate is needed repeatedly. The solution we offered was an industrial roller operated peristaltic pump with a 1.1 kW gear box, running at 34 rpm and a designed pressure of 8 bar.

Easy maintenance is one of the main benefits of these peristaltic pumps, as the only real wearing part is the hose, which is a relatively low cost part that can be sterilised or changed quite easy and in a very short time without having to dismantle the pump.