Fuel Transfer for Fuel Filtration/Cleaning OEM - Progressive Cavity Pumps

Case Study Information

- Industry: Energy & Fuel

Customer: Fuel Cleaning OEM

Location: UK

Enquiry

Our customer was using an equivalent range of pumps, however was hindered in expanding the capacities of their fuel cleaning systems by the limited flow and pressure capabilities of their existing pumps. Due to the design requirements of their systems, the client needed to use close coupled progressing cavity pumps with integral relief valves which could produce flow rates and pressures greater than 3.5 m³/hr and 3.5 bar, which their current range of pumps limited them to. Furthermore, due to the varying site conditions and locations that our customer’s equipment would be used in, they also required varying voltages (110 / 240 / 415V) and motor features such as tropicalisation. These were features that were not readily available, competitively, with their existing supplier.

Solution

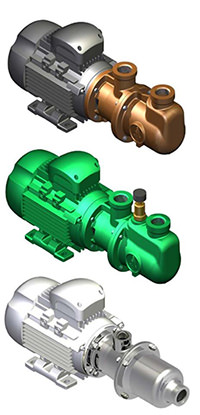

After consulting with the client to discuss the full scope of their requirements, Castle Pumps were able to offer our a compact progressive cavity which is capable of flow rates up to 14 m³/hr and pressures up to 7 bar. These units are also available with integral or external relief valves with a wide range of motor voltages (12, 24, 110, 230 & 400V / 50-60 Hz) and customisations (e.g. tropicalisation, specialised IP ratings & anti-condensation heaters). Available with cast iron, bronze and stainless steel (304 / 316) casings and a wide variety of rotor and stator materials, this range of product was perfectly suited to our OEM’s array of requirements and is now a standard component in their filtration systems.