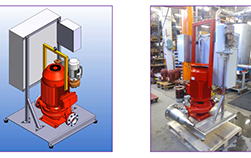

HVAC Water Supply for Deep Sea Vessel - Self Priming Centrifugal Pump Packages

Case Study Information

- Industry: Marine & Offshore

Customer: Deep Sea Pipe Laying Vessel

Location: UK / Brazil

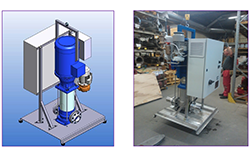

Equipment supplied

1 Qty Custom Vertical In-Line, Single Stage, Self Priming, AC / Refrigeration, Centrifugal Pump Package

- Flow: 130 m3/hr

- Total head:45 m

- Self Priming Capacity: 6 m

- Power: 30 kW

- Max Current Draw: 55.8 A

- Voltage: 400-440V-III

- Frequency: 60 Hz

- RPM: 1750

- Tropicalised for ambient temperatures up to 55ºC

- Execution: Vertical

- Pump casing: Bronze

- Impeller: Bronze

- Shaft: St. Steel AISI 316

- Flow: 60 m3/hr

- Total head: 97.5 m

- Self Priming Capacity: 6 m

- Power: 30 kW

- Max Current Draw: 56.73 A

- Voltage: 400-440V-III

- Frequency: 60 Hz

- RPM: 1750

- Tropicalised for ambient temperatures up to 55ºC

- Execution: Vertical

- Pump casing: Stainless Steel AISI 316L

- Impeller: Stainless Steel AISI 316L

- Shaft: St. Steel AISI 316

Enquiry

The customer’s vessel periodically goes into dry dock in locations where there is intermittent power supply. As a result the dock(s) couldn’t provide a guaranteed and reliable supply of AC, refrigeration and fire water systems from the dock yard. This meant that the customer had to house their 900 crew members in local hotel facilities and transport them to and from the dock yard each day during the docking period which could be as much as a couple of months. The costs related to this are astronomical.

Solution

To design, build, test & supply a portable, self priming, variable speed fire water supply pump package which can be powered by the client’s vessel (60A max supply) whilst it is in a remote dry dock.

These systems enabled the client’s vessel to be completely autonomous in the supply of fire water, AC and refrigeration services whilst it was in dry dock, enabling the crew to remain on board during the docking. This saved the client tens of thousands of pounds in hotel, logistical and down time costs, meaning that within 1 dry dock the system had paid for itself.

In addition to the pump packages Castle Pumps Ltd. also supplied over 900 m of 1½”, 4” & 6” Suction & Discharge Hose Assemblies to connect the packages to the ships on board systems. All the equipment was subsequently stored and transported in an on board container which could then be unpacked and re-used at the next dry docking.