Energy & Fuel

Diesel Generator Feed – Gear Pumps

Castle Pumps received an enquiry from a client who specialise in the design, fabrication and installation of fuel systems and their pipework. They were working on a project for which they were fabricating two duplex pump sets that would be feeding rooftop generators from a bulk diesel tank. Duplex pump systems can be for duty assist, where two pumps contribute to the total output, or duty standby, where one pump acts as a back up in the event of a failure with the first.

Fuel & Coal Dust Slurry for R&D - Progressive Cavity Pump

A new customer approached us that needed a pump for an abrasive slurry of fuel oil and coal dust. The pump needed a low flow rate and the ability to handle abrasive coal dust, whilst also needing to be controlled by a variable speed drive for testing purposes. We supplied a progressing cavity pump as its properties and capabilities were the best match for the requirements, as it is this type of pump is really good when handling solids or abrasive liquids.

Diesel Tank to Tank Transfer for Generator Supplier - Flexible Impeller Pump

When a customer enquires about a pumping system, there is usually a list of specifications that need to be met. Thanks to our team's knowledge and experience, Castle Pumps were able to fulfill our customer's exact requirements. We designed, built and supplied a ready to use system, which cut the customers extraction process time to under two hours.

Diesel Transfer for Data Centre - Self Priming Centrifugal Pump

Here at Castle Pumps we are able to source specific pumping components to produce the most bespoke of pumping systems. This customer was having trouble finding a supplier which was capable of designing and supplying a system to fit their requirements, until they came to us. We were able to design, build and supply a ready to use solution which matched their specifications.

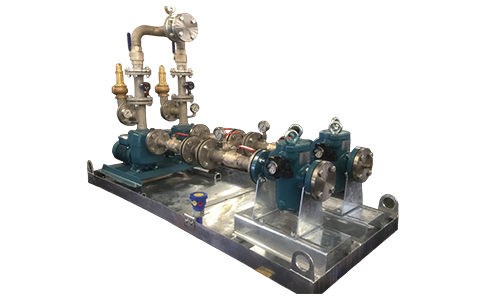

Diesel Transfer System for Generator Manufacturer - Gear Pumps

This generator manufacturer customer needed a pump set for transferring fuel in bulk with a lift height of 26.5 meters and total pipe length of 80 meters. We were able to select 2 of our gear pumps which were ideal for the requirements this customer was after.

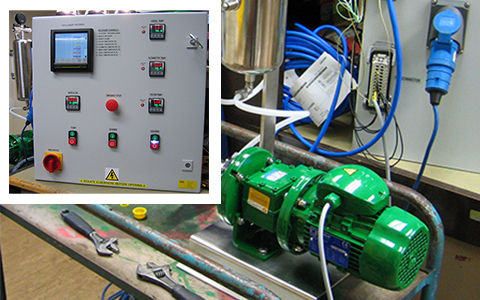

Fuel Transfer for Fuel Filtration/Cleaning OEM - Progressive Cavity Pumps

Our customer, a Fuel Cleaning OEM, was having trouble expanding the capacities of their fuel cleaning systems and required pumps that were not readily available from their previous supplier. They required a close coupled progressive cavity pump with integral relief valves to produce certain flow rates and pressures, and needed it in multiple voltages. Castle Pumps were able to offer the Nova Rotors Wobble Pump Series, which matched all of their requirements.