British Apple Company – Air Operated Diaphragm Pump

Case Study Information

- Customer: British Apple Company

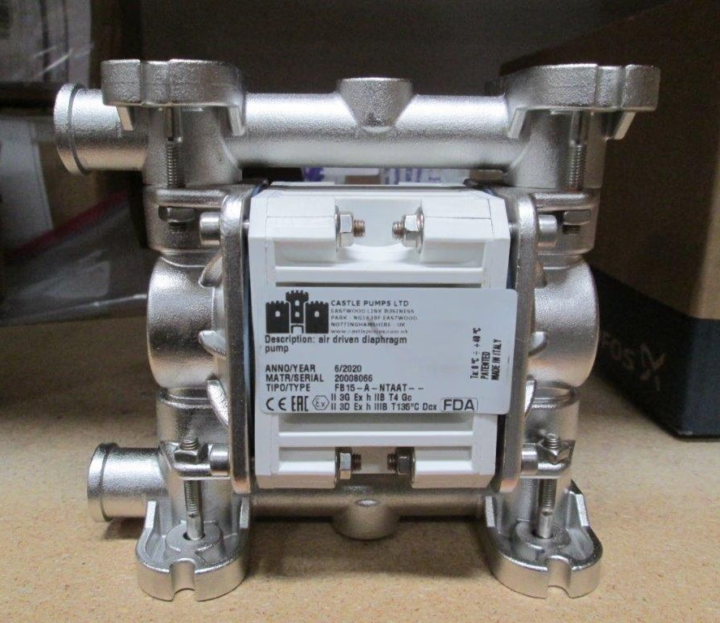

- Pump: Debem FDA Food Boxer 15 AODD Pump

- Application: Apple juice concentrate

- Industry: Food & Drink

Enquiry

Castle Pumps received an enquiry from an apple grower and supplier of apple juice concentrate to cider manufacturers in the UK and abroad. The pump they needed was to transfer small quantities at a time of the apple juice concentrate that they package and sell on as an ingredient to be used in cider production. The initial challenge with this enquiry was that the customer wasn’t sure of the viscosity of the liquid, other than that it was thicker than water.

Due to the product being for human consumption, the solution of course needed to be a food grade pump and easy to clean to ensure no contamination of the apple juice concentrate.

Key challenges:

Approved as safe for food handling

Can handle low flow rates

The unknown viscosity of the fluid

Solution

Equipment Supplied

1 x Debem Food Boxer 15 AODD Pump

- Max flow: 17l/min

- Fluid: Concentrated apple juice

- Connections: G 3/8" F BSPP connections

- Body: AISI 316 – FOOD GRADE

- Diaphragms: HYTREL+PTFE – FOOD GRADE

- Balls: INOX – FOOD GRADE

- Ball seats: INOX – FOOD GRADE

Given the combination of requirements and that the customer had compressed air on site, we selected a Debem Food Boxer Air Operated Diaphragm Pump for this application. Firstly, the FOOD BOXER is an FDA approved food industry pump constructed of electro polished AISI 316 with food grade diaphragm, making it safe for the transfer of apple juice.

Viscosity is an important factor in selecting a pump, as some pump types are able to handle thinner or thicker fluids betters than others. Whilst the customer was unable to tell us the exact viscosity, upon asking him to liken it to another fluid, we were able to determine that it was similar to a free-flowing caramel. Using our application experience we were able to then select the right model in the Food Boxer food grade aodd pump range that could handle this viscosity whilst operating at a low flow rate.

This model of air operated diaphragm pump also provides the customer with a number of benefits. Firstly, it is relatively low cost to maintain thanks to its long-life diaphragms designed for more than 50M cycles, and its much fewer wearing parts relative to equivalent brands of AODD pump. Secondly, it is able to be dry run without damage; a useful feature for the client when filling the packaging when the larger container they are filling from becomes empty. Finally, the absence of seals in an air operated diaphragm pump reduces the chance of leaking product, which for a sticky product such as apple juice concentrate is ideal.

Looking to upscale your food production?

From viscous, solid laden sauces to shear sensitive creams to fruit juices or wine, we can specify the right food processing pump so that you can increase production and reduce costs.