Bilge Water Transfer – Progressive Cavity Pumps

Case Study Information

- Customer: Marine supplier

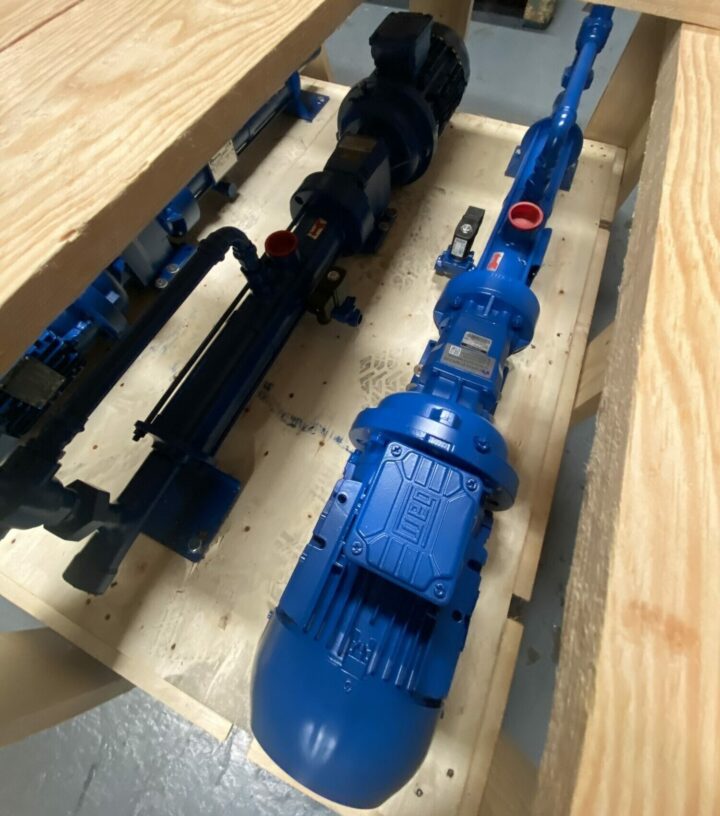

- Pump: Azcue KB Progressive Cavity Pump

- Application: Bilge water transfer

- Industry: Marine & Offshore

Enquiry

One of our repeat clients, a supplier of parts and products to the marine market, approached us with an enquiry for three pumps for their customer. These were needed for the pumping of bilge water onboard a vessel.

Water collected in the bilge of a ship is typically harsh in nature due to the presence of oily sludges, waste and debris that may be contaminating it. Therefore, unlike the clean water pumps they had onboard, a typical centrifugal pump is not suitable as it is likely to clog, damage impellers and leak.

Key challenges:

Potential presence of solids

Unknown, inconsistent viscosity

Marine type approval for use onboard

Solution

Equipment Supplied

Model: Azcue KB 20S30 Progressive Cavity Pump

- Flow Rate: 2 m3/h

- Head: 30m

- Fluid: Bilge water

- Orientation: Horizontal

- Voltage: 380, Three Phase

- Material: Cast Iron

- Suction/Discharge: 1"

- Certifications: Marine Type Approval

- Drive: Close coupled motor

Being for a marine application, when specifying a solution we consulted our range of Azcue pumps for which we are the UK agent. Azcue have been manufacturing marine type approved pumps for over 100 years, with class certification from Lloyds, ABS and Bureau Veritas available.

Based upon the duty requirements and the contaminated nature of the bilge water, we specified the Azcue KB progressive cavity pump as the most ideal solution for this bilge pump enquiry for a number of reasons.

Firstly, the continuous cavities between the rotor and stator means that even large solids that may have found themselves in the bilge can be handled without clogging or damage to the pump. Progressive cavity pumps are also able to handle viscosities up to 200,000 cP, meaning any sludge present in the bilge water can be efficiently handled with ease. This was important as due to the inconsistency of bilge water, it is difficult to specify an exact viscosity that the pump needs to handle.

Finally, the design operates with low shear thanks to its low internal velocity when pumping the fluid. This means that any oil droplets present in the water are kept intact, allowing the oily water separator that the bilge water goes to, to work most effectively.

Looking for a reliable bilge pump?

When it comes to marine bilge pumping systems, reliability is vital. As the UK agent of marine type approved Azcue pumps, we have a solution you can trust.